Atlas Copco ZR 110-160 VSD (FF) Oil-free Compressors

$20,000.00

The Atlas Copco ZR 110-160 VSD (FF) (ZR 110 VSD, ZR 132 VSD, ZR 145, ZR 160 VSD) Oil-free rotary screw air compressors have been designed for energy efficiency, reliability and serviceability.

The Atlas Copco ZR 110-160 VSD (FF) (ZR 110 VSD, ZR 132 VSD, ZR 145, ZR 160 VSD) Oil-free rotary screw air compressors have been designed for energy efficiency, reliability and serviceability. The perfect oil-free air solution for your application. Atlas Copco ZT VSD compressors are known among the best oil-free compressors in the market.

Contents

The right air quality to protect your products

Compressed air is used in a wide variety of manufacturing and commercial operations. Air is generated from the ambient atmosphere around the compressor and typically would contain contaminants in the form of dust and water which are two naturally occurring impurities while a third impurity which is oil typically gets added to compressed air due to the compression process. Oil though can be avoided/eliminated by using our 100% oil free compressors.

|

|

|

|

100% oil-free compressed air For over 60 years Atlas Copco has pioneered the development of oil-free air technology. Resulting in the largest range of air compressors and blowers within our industry. Through continuous research and development, we achieved a new milestone, setting the standard for air purity as the first manufacturer to be awarded ISO 8573-1 CLASS 0 certification. CLASS 0 certification means zero risk of oil contamination from our products. |

Air treatment Untreated compressed air contains moisture and possibly dirt particles that can damage your air system and contaminate your end product. The resulting maintenance costs far exceed air treatment costs. Atlas Copco believes in effective prevention and provides a complete range of air treatment solutions to protect investments, equipment, production processes and end products. |

Avoid downtime Low quality air heightens the risk of corrosion, which can lower the life span of production equipment. The air treatment solutions produce clean air that enhances your system’s reliability, avoiding costly downtime and production delays. Compressed air coming into contact with your final products should not affect their quality. Atlas Copco provides clean, dry air to protect your production and reputation in the market. |

Smart AIR solutions: class-leading compressed air products

As a compressor is only one component in a compressed air system, true efficiency can only be achieved by looking at the bigger picture. Atlas Copco smart AIR solutions are complete systems optimized for energy performance, reliability, and output quality. Smart Air solutions are based on a range of class- leading compressed air products, fully optimized to work better together for the most efficient and reliable combination of a compressor with our air and gas equipment. These solutions can include dryers, filters, controllers, energy recovery systems, nitrogen or oxygen generators, air receivers, coolers, or boosters specified to your needs. If you have multiple compressors, the combination of machines is important for the efficiency of the complete system. And if you have three or more compressors, a central controller will allow smarter, more effective control than individual controllers.

| ①Central controllers

Central control reduces both the average pressure band and the operating pressure of your machines. A pressure reduction of 1 bar (14.5 psi) lowers energy consumption by 7% and air leakages by 13%. Multiple functions are embedded in the Optimizer 4.0 which regulate pressure, capacity, and speed. |

④Ventilation

Compressors generate heat. Adequate evacuation of this heat will improve the performance of compressors and dryers alike. |

| ②Reliable, energy-efficient compressors

All smart AIR solutions start with selection of the correct components in the correct combination. Choosing energy-efficient compressors and paying special attention to the mix of compressors are major factors. Our soundproof design contributes to a better working environment around the compressors. Low maintenance is also a priority to reduce machine downtime and improve the availability of compressed air. |

⑤Ventilation

Compressors generate heat. Adequate evacuation of this heat will improve the performance of compressors and dryers alike. |

| ③Variable Speed Drive (VSD) compressors

In most applications, demand for compressed air varies widely. Adding one or multiple VSD compressors will significantly improve the energy efficiency of the total installation, the stability of compressed air pressure, and reliability, thanks to more the stable regime of each machine. |

⑥Compressed air dryers

Choosing the right dryer technology for the specific compressed air quality requirement is essential to ensure the reliability and energy efficiency of the entire set-up. Our Full Feature concept integrates the best dryer for the installation and process. The benefits include reduced installation cost, time, and complexity; integrated control of dryers and compressors; and a reduction in connecting pipes, which decreases the chance of leakages and extra pressure drops. Full Feature solutions also save significant space in the compressor room. |

| ⑦Compressed air filters

The correct filter grade to correspond with air quality requirements is an important part of a smart AIR solution. This goes hand-in- hand with correct filter maintenance to protect the reliability of the installation and increase energy efficiency. |

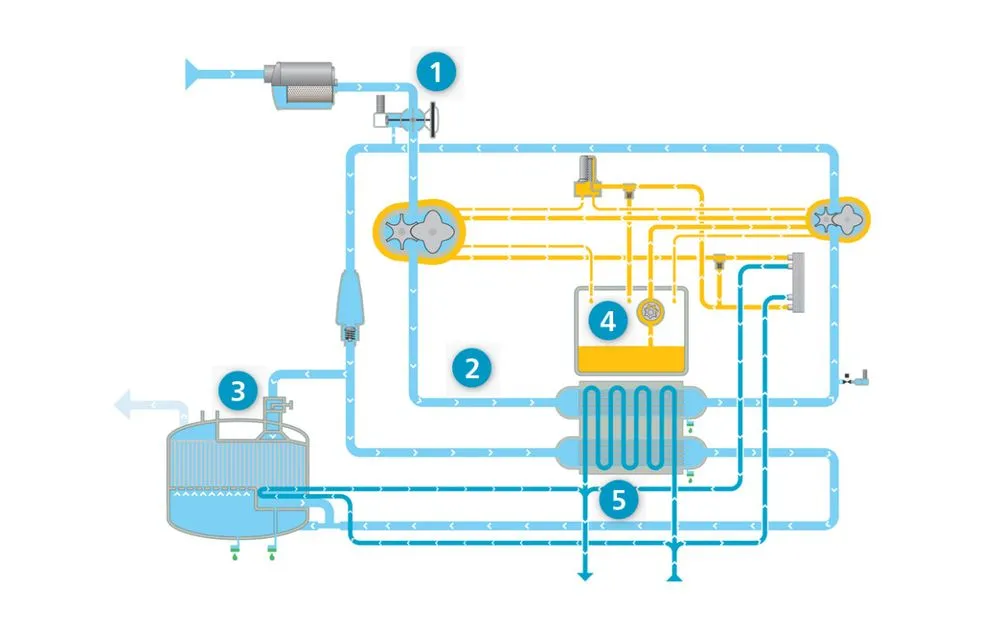

Atlas Copco ZR 110-160 VSD (FF) Oil-free Compressors Flowchart

| ①Filtration & first compression

The light blue flow represents the air. Air is drawn into the compressor through the inlet filter, where the air is cleaned. It then passes through the throttle valve with integrated blow off valve, which takes care of the load/unload regulation. |

②Cooling & second compression

After the intercooler, the air passes through a moisture separation system before entering the high pressure stage. In the high pressure stage the pressure is brought to the final pressure. |

| ③Cooling & drying

The air at the outlet of the high pressure stage is split into two parts. One part goes via the pulsation damper with integrated check valve to the aftercooler, where it is cooled down and moisture is separated and evacuated. A second part goes directly to the regeneration area of the heat compression MD dryer. |

④Oil flow

The yellow flow is the oil path within the compressor. The oil pump sucks oil from the oil sump and pumps it through the oil cooler and a high efficiency filter to deliver cool, clean oil to the bearings and the gears. The oil then flows back to the gear casing. |

| ⑤Water flow

The dark blue flow represents the water. Water is used in the oil cooler, the intercooler, and the aftercooler, as well as in the integrated dryer. |

Atlas Copco ZR 110-160 VSD (FF) Oil-free Compressors Technical Specifications

ZR 110-160 (FF) Technical Specifications

Metric

| Type | Working pressure (1) | Free Air Delivery (2) | Installed motor power (3) kW |

Noise level (4) dB(A) |

|

| bar(e) | l/s | m³/min | |||

| ZR 110 – 7.5 | 7.5 | 318 | 19.1 | 110 | 74 |

| ZR 110 – 8.6 | 8.6 | 297 | 17.8 | ||

| ZR 110 – 10 | 10 | 278 | 16.7 | ||

| ZR 132 – 7.5 | 7.5 | 363 | 21.8 | 132 | |

| ZR 132 – 8.6 | 8.6 | 339 | 20.3 | ||

| ZR 132 – 10 | 10 | 314 | 18.8 | ||

| ZR 145 – 7.5 | 7.5 | 393 | 23.6 | 145 | |

| ZR 145 – 8.6 | 8.6 | 364 | 21.8 | ||

| ZR 145 – 10 | 10 | 351 | 21.1 | ||

| ZR 160 – 7.5 | 7.5 | 434 | 26 | 160 | |

| ZR 160 – 8.6 | 8.6 | 418 | 25.1 | ||

| ZR 160 – 10 | 10 | 399 | 23.9 | ||

Imperial

| Type | Working pressure (1) | Free Air Delivery (2) | Installed motor power (3) hp |

Noise level (4) dB(A) |

|

| psig | l/s | cfm | |||

| ZR 110 – 7.5 | 100 | 318 | 674 | 150 | 74 |

| ZR 110 – 8.6 | 125 | 297 | 629 | ||

| ZR 110 – 10 | 145 | 278 | 589 | ||

| ZR 132 – 7.5 | 100 | 363 | 769 | 175 | |

| ZR 132 – 8.6 | 125 | 339 | 718 | ||

| ZR 132 – 10 | 145 | 314 | 665 | ||

| ZR 145 – 7.5 | 100 | 393 | 832 | 200 | |

| ZR 145 – 8.6 | 125 | 364 | 771 | ||

| ZR 145 – 10 | 145 | 351 | 743 | ||

| ZR 160 – 7.5 | 100 | 434 | 919 | 215 | |

| ZR 160 – 8.6 | 125 | 418 | 885 | ||

| ZR 160 – 10 | 145 | 399 | 845 | ||

ZR 110-160 VSD (FF) Technical Specifications

Metric

| Type | Working Pressure (1) | Free Air Delivery (2) | Installed motor power (3) | Noise lever (4) | ||

| bar(e) | l/s | m³/min | kW | dB(A) | ||

| ZR 110 VSD – 8.6 | Minimum | 4 | 101-320 | 6.1-19.2 | 110 | 74 |

| Effective | 7 | 101-319 | 6.0-19.2 | |||

| Maximum | 8.6 | 100-298 | 6.0-17.9 | |||

| ZR 110 VSD – 10.4 | Minimum | 6 | 168-292 | 10.1-17.5 | ||

| Effective | 9 | 167-292 | 10.0-17.5 | |||

| Maximum | 10.4 | 193-277 | 11.6-16.6 | |||

| ZR 132 VSD – 8.6 | Minimum | 4 | 108-357 | 6.5-21.4 | 132 | |

| Effective | 7 | 107-357 | 6.4-21.4 | |||

| Maximum | 8.6 | 107-336 | 6.4-20.2 | |||

| ZR 132 VSD – 10.4 | Minimum | 6 | 167-331 | 10.0-19.9 | ||

| Effective | 9 | |||||

| Maximum | 10.4 | 193-316 | 11.6-19.0 | |||

| ZR 160 VSD – 8.6 | Minimum | 4 | 124-412 | 7.4-24.7 | 160 | |

| Effective | 7 | 123-411 | 7.4-24.6 | |||

| Maximum | 8.6 | 123-386 | 7.4-23.0 | |||

| ZR 160 VSD – 10.4 | Minimum | 6 | 167-378 | 10.0-22.6 | ||

| Effective | 9 | |||||

| Maximum | 10.4 | 193-361 | 11.6-21.6 | |||

Imperial

| Type | Working Pressure (1) | Free Air Delivery (2) | Installed motor power (3) | Noise lever (4) | ||

| psig | l/s | cfm | kW | dB(A) | ||

| ZR 110 VSD – 8.6 | Minimum | 60 | 101-320 | 214-677 | 150 | 74 |

| Effective | 100 | 101-319 | 213-676 | |||

| Maximum | 125 | 100-298 | 212-632 | |||

| ZR 110 VSD – 10.4 | Minimum | 90 | 168-292 | 355-619 | ||

| Effective | 130 | 167-292 | 354-619 | |||

| Maximum | 150 | 193-277 | 409-586 | |||

| ZR 132 VSD – 8.6 | Minimum | 60 | 108-357 | 228-757 | 175 | |

| Effective | 100 | 107-357 | 227-757 | |||

| Maximum | 125 | 107-336 | 226-713 | |||

| ZR 132 VSD – 10.4 | Minimum | 90 | 167-331 | 354-702 | ||

| Effective | 130 | 353-701 | ||||

| Maximum | 150 | 193-316 | 409-670 | |||

| ZR 160 VSD – 8.6 | Minimum | 60 | 124-412 | 261-872 | 215 | |

| Effective | 100 | 123-411 | 261-871 | |||

| Maximum | 125 | 123-386 | 261-817 | |||

| ZR 160 VSD – 10.4 | Minimum | 90 | 167-378 | 354-801 | ||

| Effective | 130 | 353-801 | ||||

| Maximum | 150 | 193-361 | 409-765 | |||

Dimensions

Metric

| Type | L | W | H | Weight |

| mm | kg | |||

| Water cooled | Water cooled | Water cooled | Water cooled | Water cooled |

| ZR 110-160 (VSD) | 2431 | 1660 | 2000 | 2920 |

| ZR 110-160 (VSD) FF iMD | 3400 | 3720 | ||

Imperial

| Type | L | W | H | Weight |

| inch | lb | |||

| Water cooled | Water cooled | Water cooled | Water cooled | Water cooled |

| ZR 110-160 (VSD) | 96 | 65 | 79 | 6440 |

| ZR 110-160 (VSD) FF iMD | 134 | 8200 | ||

Brochure

If you need Atlas Copco ZR 110-160 VSD (FF) Oil-free Compressors brochure, please click the link below to view or download it.

Atlas Copco ZR ZT 110-160 (VSD) FF Oil-free Rotary Screw Air Compressors

| Weight | 2920 kg |

|---|---|

| Dimensions | 340 × 166 × 200 cm |

| 1-9 Pcs | $20000.00 |

| ≥10 Pcs | $15000.00 |

| Certificate | ISO 8573-1 CLASS 0 |

| Country of Origin | CN |

| Delivery Time | 60-90 Days |

| MOQ | 1 Piece |

| Packing | Wooden Crate |

| Product Quality | Brand-New Original |

| Transaction Mode | CFR, CIF, DAP, DDP, DPU, EXW, FCA, FOB |

Anonymous_buyer –

We are very satisfied and will continue working with BOAO.

We purchased the Atlas Copco ZR 110 VSD FF oil-free rotary screw air compressor from BOAO Air Compressor Co., Ltd. for our food processing plant, and the performance has been excellent. The compressor delivers clean, oil-free air that meets our hygiene standards, and the pressure remains stable even during peak production hours. Energy consumption is noticeably lower compared to our previous machine. BOAO handled the shipment professionally, and their team followed up to make sure installation went smoothly. The unit has improved both efficiency and air quality in our factory.