Atlas Copco GA 37-110 VSD⁺ (GA37, GA45, GA55, GA75, GA90, GA110) Oil-injected rotary screw compressors are not just a ground-breaking new compressor range, it is an operational transformation. It reduces your energy costs by 50% on average and maximizes uptime, even in the harshest conditions. Driving this next-level performance: Atlas Copco’s Variable Speed Drive, a powerful interior permanent magnet motor, and our in-house developed Neos inverter. Thanks to its compact vertical design, the GA 37-110 VSD⁺ fits in even the smallest compressor room. Including yours? Discover how the GA 37-110 VSD⁺ can transform your operational environment today.

Inside the robust GA 37L-75 VSD+

| 1.Interior Permanent Magnet (iPM) motor

• Oil-cooled motor.

• Optimal cooling for all speeds and ambient conditions.

• Designed in-house in Belgium.

• Oil-lubricated motor bearing: no (re)grease(ing), increased uptime.

• IP66: pressure tight.

• Permanent magnets. |

2.New compressor element

• New improved rotor profile.

• Reduced pressure losses.

• Optimized in and outlet portals. |

| 3.Direct drive

• Vertical design, less parts.

• Oil-cooled, pressure-tight.

• No gears or belts, no shaft seal. |

4.Inlet filter

• Heavy duty.

• Maintenance every 4,000 hours.

• Pressure drop indicator. |

| 5.Radial fan

- Compacto.

- Bajo nivel de ruido.

- Alta capacidad para una refrigeración optimizada. |

6.Classic cooler design

• Integrated water separation.

• Separate oil/air cooler.

• Easy access for maintenance. |

| 7.Innovative Neos inverter

• Atlas Copco’s in-house designed

• inverter now also controls iPM motors.

• IP5x protection.

• Robust aluminum enclosure for trouble-free operation in the harshest conditions.

• Fewer components: compact, simple and

• user-friendly. |

8.Integrated dryer

• Extra compact footprint.

• Refrigerant R410A. |

| 9.Elektronikon® Touch controller

• High-tech controller with warning indications, compressor shut-down and maintenance scheduling.

- Fácil de usar y diseñada para rendir en las condiciones más duras.

- Monitorización remota SMARTLINK estándar para maximizar el rendimiento del sistema de aire y el ahorro de energía.

- Control opcional de varios compresores (2, 4 ó 6 compresores). |

10.Sentinel valve

• Optimizes the inlet flow of the air end.

• No blow-off losses.

• Full aluminum design: maintenance-free. |

| 11.VSD+ Neos cubicle

• VSD+ is superior to idling machines.

- Los componentes eléctricos permanecen fríos, lo que aumenta su vida útil.

• Dedicated drive for iPM technology motors.

• Heat dissipation of inverter in separate compartment. |

|

Inside the powerful GA 75L-110 VSD+

| 1.Interior Permanent Magnet (iPM) motor

• Compact, customized design for optimal cooling by oil.

• Designed in-house in Belgium.

• IP66 protection rating.

• No cooling air flow required.

• Oil-lubricated motor bearing:no (re)grease(ing) and increased uptime. |

2.New compressor element

• Improved efficiency.

• Made by Atlas Copco.

• Robust and silent. |

| 3.Direct drive

• Vertical design, less parts.

• Oil-cooled, pressure-tight.

• No gears or belts, no shaft seal. |

4.Inlet filter

• Heavy duty.

• Pressure drop indicator.

• Maintenance every 4,000 hours. |

| 5.Cooling fan

• Already compliant with future ERP2020 efficiency.

• Optimized, application-specific design results in low noise and high efficiency.

• Condensation prevention cycle based on inlet humidity sensor. |

6.Classic cooler design

• Integrated water separation.

• Separate oil/air cooler.

• Easy access for maintenance. |

| 7.Integrated dryer

• Ensures excellence in air quality.

• Incorporates optional UD+ filter to meet ISO 8573-1 Quality Class 1.4.2.

• True plug-and-play design eliminates cost of installing a separate dryer. |

8.Innovative Neos inverter

• Atlas Copco’s in-house designed inverter now also controls iPM motors.

• IP5x protection.

• Robust aluminum enclosure for trouble-free operation in the harshest conditions.

• Fewer components: compact, simple and user-friendly. |

| 9.Elektronikon® Touch controller

• High-tech controller with warning indications, compressor shut-down and maintenance scheduling.

- Fácil de usar y diseñada para rendir en las condiciones más duras.

- Monitorización remota SMARTLINK estándar para maximizar el rendimiento del sistema de aire y el ahorro de energía.

- Control opcional de varios compresores (2, 4 ó 6 compresores). |

10.VSD+ Neos cubicle

- VSD+ is superior to idling machines.

• Electrical components remain cool, enhancing theirlifetime.

• Dedicated Neos drive for iPM technology motors.

• Heat dissipation of inverter in separate compartmen |

Technical specifications GA 37-110 VSD⁺

| Tipo de compresor |

Max. working pressure |

Capacidad FAD* (mín-máx) |

Potencia del motor instalado |

Nivel de ruido** |

Weight WorkPlace |

Weight WorkPlace Full Feature |

| bar(e) |

psig |

l/s |

m³/h |

cfm |

kW |

hp |

dB(A) |

kg |

kg |

| GA37VSD**** |

4 |

58 |

15-116 |

55-419 |

32-246 |

37 |

50 |

67 |

376 |

500 |

| 7 |

102 |

15-115 |

53-413 |

31-243 |

37 |

50 |

67 |

376 |

500 |

| 9.5 |

138 |

17-102 |

62-368 |

36-216 |

37 |

50 |

67 |

376 |

500 |

| 12.5 |

181 |

16-87 |

59-312 |

35-183 |

37 |

50 |

67 |

376 |

500 |

| GA37LVSD+ |

4 |

58 |

26-133 |

94-479 |

55-282 |

37 |

50 |

67 |

860 |

1060 |

| 7 |

102 |

26-132 |

93-475 |

55-279 |

37 |

50 |

67 |

860 |

1060 |

| 9.5 |

138 |

25-116 |

89-418 |

53-246 |

37 |

50 |

67 |

860 |

1060 |

| 12.5 |

181 |

38-99 |

138-355 |

81-209 |

37 |

50 |

67 |

860 |

1060 |

| GA45VSD* |

4 |

58 |

26-159 |

94-573 |

55-337 |

45 |

60 |

67 |

860 |

1060 |

| 7 |

102 |

26-157 |

93-565 |

55-332 |

45 |

60 |

67 |

860 |

1060 |

| 9.5 |

138 |

25-137 |

89-494 |

53-291 |

45 |

60 |

67 |

860 |

1060 |

| 12.5 |

181 |

38-115 |

138-359 |

81-211 |

45 |

60 |

67 |

860 |

1060 |

| GA55VSD* |

4 |

58 |

26-189 |

93-680 |

55-400 |

55 |

75 |

67 |

900 |

1100 |

| 7 |

102 |

26-188 |

94-677 |

55-399 |

55 |

75 |

67 |

900 |

1100 |

| 9.5 |

138 |

26-166 |

93-598 |

55-352 |

55 |

75 |

67 |

900 |

1100 |

| 12.5 |

181 |

40-140 |

145-504 |

85-297 |

55 |

75 |

67 |

900 |

1100 |

| GA75VSD* |

4 |

58 |

26-226 |

93-815 |

55-480 |

75 |

100 |

70 |

920 |

1120 |

| 7 |

102 |

27-225 |

97-809 |

57-476 |

75 |

100 |

70 |

920 |

1120 |

| 9.5 |

138 |

27-198 |

96-712 |

57-419 |

75 |

100 |

70 |

920 |

1120 |

| 12.5 |

181 |

42-167 |

150-600 |

88-353 |

75 |

100 |

70 |

920 |

1120 |

| GA75LVSD* |

4 |

58 |

47-269 |

169-967 |

100-569 |

75 |

100 |

73 |

1207 |

1496 |

| 7 |

102 |

48-266 |

172-957 |

101-563 |

75 |

100 |

73 |

1207 |

1496 |

| 9.5 |

138 |

58-235 |

210-847 |

124-498 |

75 |

100 |

73 |

1207 |

1496 |

| 12.5 |

181 |

70-194 |

252-699 |

149-411 |

75 |

100 |

73 |

1207 |

1496 |

| GA90VSD* |

4 |

58 |

48-311 |

174-1121 |

102-660 |

90 |

125 |

74 |

1213 |

1503 |

| 7 |

102 |

49-306 |

176-1101 |

104-548 |

90 |

125 |

74 |

1213 |

1503 |

| 9.5 |

138 |

60-269 |

215-969 |

127-570 |

90 |

125 |

74 |

1213 |

1503 |

| 12.5 |

181 |

71-218 |

255-784 |

150-461 |

90 |

125 |

74 |

1213 |

1503 |

| GA110VSD* |

4 |

58 |

47-348 |

170-1251 |

100-736 |

110 |

150 |

76 |

1222 |

1573 |

| 7 |

102 |

49-345 |

175-1241 |

103-731 |

110 |

150 |

76 |

1222 |

1573 |

| 9.5 |

138 |

59-309 |

211-1111 |

124-554 |

110 |

150 |

76 |

1222 |

1573 |

| 12.5 |

181 |

71-268 |

254-965 |

150-568 |

110 |

150 |

76 |

1222 |

1573 |

* Unit performance measured according ISO 1217 ed. 4 2009, annex E, latest edition.

** Mean noise level measured at a distance of 1 m at max. working pressure according to ISO 2151: 2004 using ISO 9614/2 (sound intensity method); tolerance 3 dB(A).

***This model is part of the GA 7-37 VSD+ range, a different series with different specifications.FAD is measured at the following effective working pressures:

– 4 bar(e)

– 7 bar(e)

– 9.5 bar(e)

- 12,5 bar(e)

Presión máxima de trabajo:

13 bar(e) (188 psig)

Condiciones de referencia:

- Presión absoluta de entrada 1 bar (14,5 psi).

– Intake air temperature 20°C/68°F.

Dimensions GA 37-110 VSD⁺

| Dimensiones |

Estándar |

Reportaje completo |

| D (mm) |

W (mm) |

H (mm) |

D (pulg.) |

W (in) |

H (pulg.) |

D (mm) |

W (mm) |

H (mm) |

D (pulg.) |

W (in) |

H (pulg.) |

| GA 37 VSD+ |

780 |

811 |

1590 |

30.71 |

31.93 |

62.60 |

780 |

1273 |

1590 |

30.71 |

50.12 |

62.6 |

| GA 37L-75 VSD+ |

1100 |

1153 |

1968 |

43.31 |

45.39 |

77.48 |

1100 |

1656 |

1968 |

43.31 |

65.20 |

77.48 |

| GA 75L-110 VSD+ |

1400 |

1300 |

1968 |

55.12 |

51.18 |

77.48 |

2178 |

1300 |

1968 |

85.75 |

51.18 |

77.48 |

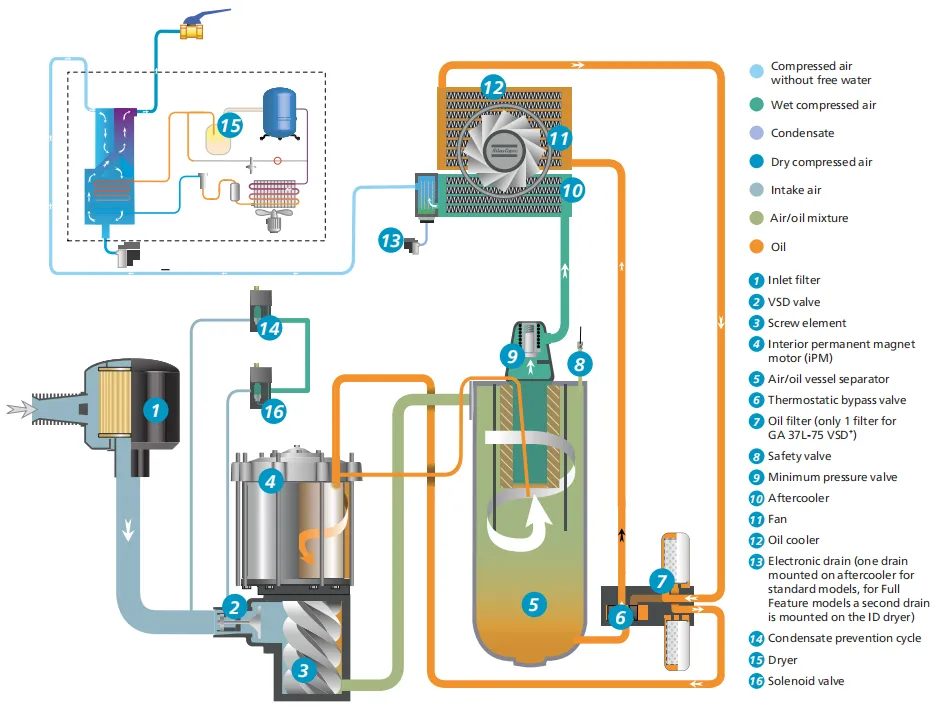

Flow chart GA 37L-110 VSD⁺

Folleto

If you need Atlas Copco GA37-110 VSD⁺ Oil-injected Air Compressors brochure, please click the link below to view or download it.

Atlas Copco GA37-110 VSD⁺ Compresores de aire con inyección de aceite

Consulta

Anónimo_comprador -

Truly a reliable workhorse that boosts our production efficiency!

We purchased the Atlas Copco GA110 VSD⁺ Oil-injected Air Compressor from Seadweer. It’s compact with a small footprint, fits perfectly in our workshop, and delivers stable high-pressure air for metal processing. The VSD technology cuts energy costs by 35% vs. our old unit, runs quietly, and handles 55°C high-temperature environments effortlessly. Fast delivery, easy one-person maintenance, and genuine quality—truly a reliable workhorse that boosts our production efficiency!

Anónimo -

We're totally satisfied with this investment!

This Seadweer-supplied GA110 VSD⁺ compressor has exceeded our expectations. The MK5 touchscreen controller makes monitoring a breeze, remote access works flawlessly, and the oil-injected design ensures long-lasting performance with minimal wear. It provides clean, dry air for our pneumatic tools, requires no heavy lifting for servicing, and the integrated system reduces downtime. Professional pre-sales consultation and prompt after-sales support—we’re totally satisfied with this investment!