Atlas Copco ZT 110-160 VSD (FF) Oil-free Compressors

$20,000.00

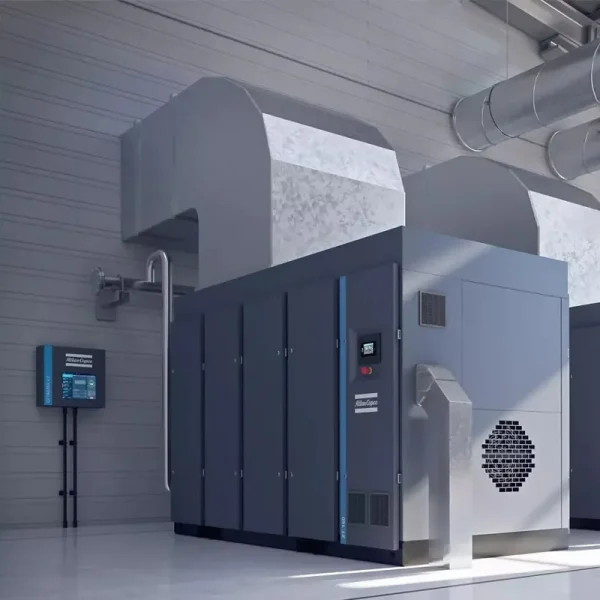

The Atlas Copco ZT 110-160 VSD (FF) Oil-free compressors (ZT 110, ZT 132, ZT 145, ZT 160) are focused on effectively saving energy, ensuring product safety – only oil-free machines exclude contamination risks for 100%

The shortest route to superior productivity is to minimize operational cost while maintaining an uninterrupted supply of the right quality of air. The Atlas Copco ZT 110-160 VSD (FF) (ZT 110, ZT 132, ZT 145, ZT 160) Oil-free rotary screw air compressors are focused on effectively saving energy, ensuring product safety – only oil-free machines exclude contamination risks for 100% – and guaranteeing the utmost reliability around the clock. And not just today, but day after day, year after year, with minimal maintenance cost, few service interventions and long overhaul intervals.

Contents

ZT 90-160 VSD Engineered for the highest reliability

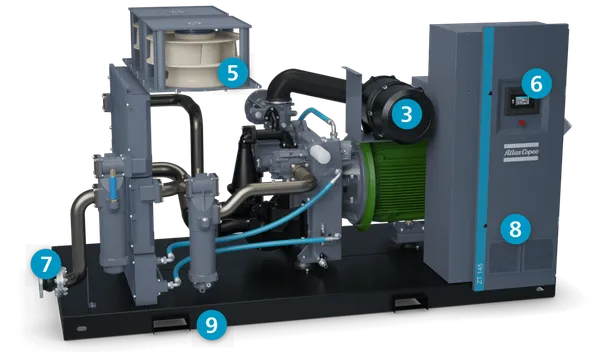

ZT 90-160 VSD Left View ZT 90-160 VSD Left View |

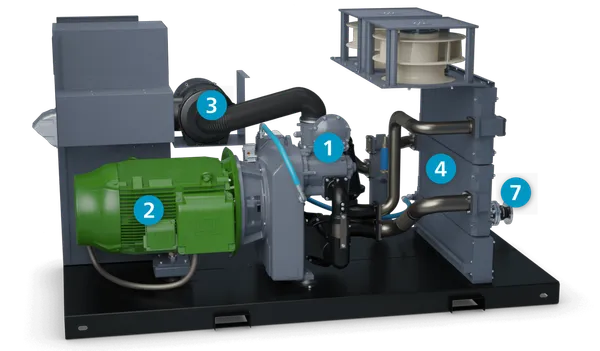

ZT 90-160 VSD Right View ZT 90-160 VSD Right View |

| ①Oil-free air (Class 0) •Unique Z seal design guarantees certified oil-free air. •Superior rotor coating for high efficiency and durability. •Cooling jackets ensure world class compression in varying conditions. |

⑥Advanced touch screen monitoring system •User-friendly Elektronikon® Touch with enhanced connectivity potential. •Integrated smart algorithms optimize system pressure and maximize energy efficiency. •Warning indications, maintenance scheduling and online visualization of the machine’s condition. |

| ②Robust motor •IP 55 TEFC motor protects against dust, chemicals, and humidity. •Continuous operation under severe ambient temperature conditions. |

⑦Complete Plug-and-play package •All-in-one solution including internal piping, coolers, motor, drive, lubrication, and control system. •Fault-free installation. •Easy commissioning and quick start-up. |

| ③Efficient intake air filtration •2-stage dust removal system (99.9% for 3 micron). •Minimum intake losses and low pressure drop. •Efficient protection of the compressor. |

⑧Soundproof design •Silenced canopy improves conditions for workers in the immediate environment. •Optimized internal ducting and integrated pulsation damper to reduce the noise level. |

| ④High performing coolers •Compact and efficient design with low air approach temperature and low pressure drop. •Water separator separates condensate from compressed air. •Low moisture carry-over protects downstream equipment. |

⑨Quick, easy maintenance •Minimal service time with service kits grouped together for ease of access. •All components are designed for serviceability and long lifetime. •Optional service plans available to extend the warranty. |

| ⑤Reliable load/unload regulation •No external air supply required. •Mechanical interlock of inlet and blow-off valve. •Low unload power. |

Reducing consumption throughout your process

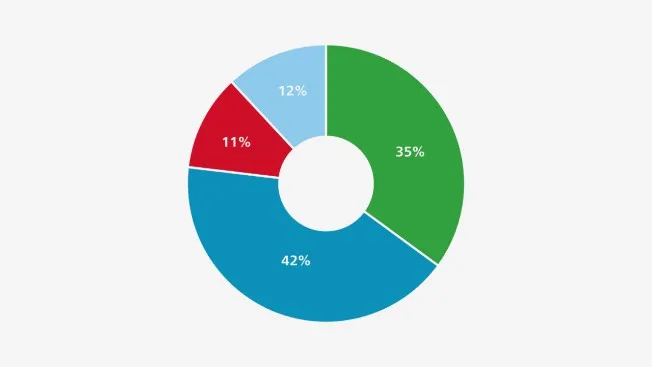

Did you know that compressed air generation amounts to over 40% of a plant’s total electricity bill? And that energy consumption can account for over 80% of a compressor’s lifecycle cost? Atlas Copco pioneered Variable Speed Drive (VSD) technology in the compressed air industry to help businesses reduce energy consumption and increase their profits. While continuing to invest in VSD, we have also developed a range of control, monitoring and energy recovery technologies that reduce running costs while protecting the environment for future generations.

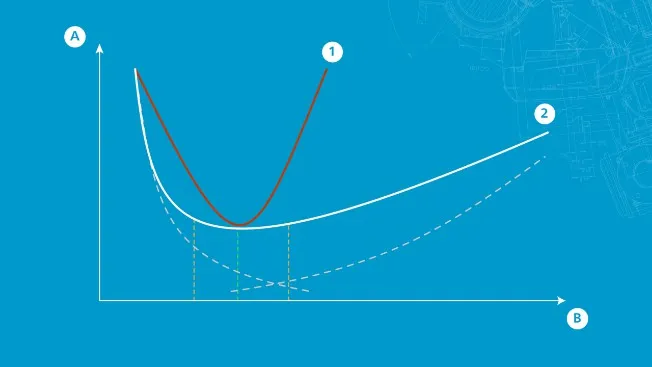

What is Variable Speed Drive (VSD)?

Atlas Copco’s VSD technology automatically adjusts the motor speed to air demand, reducing energy consumption by up to 35% and cutting the compressor’s life cycle cost by an average of 22%. In addition, lowered system pressure with VSD dramatically minimizes energy use across your production.

42% = Energy |

A = Losses |

|

|

|

|

SMARTLINK for expert monitoring Knowing the status of your compressed air equipment at all times is the key to efficiency and availability. SMARTLINK provides customized reports on your compressor room’s energy performance as well as early warnings, and timely component replacement alerts to increase uptime and prevent production loss. |

Dual set-point and automatic stop Most production processes create fluctuating levels of demand which can lead to energy waste in low use periods. Using the Elektronikon® unit controller, you can switch manually or automatically between two different setpoints to optimize energy use and reduce costs at low use times. In addition, the sophisticated algorithm runs the drive motor only when needed. As the desired setpoint is maintained while the drive motor’s run time is minimized, energy consumption is kept to a minimum. |

Components designed for efficiency Our engineers took every opportunity to reduce energy consumption in the ZT and ZR compressors. The element has a superior coating for increased efficiency. High- performing intake filtration ensures minimum losses and low pressure drop. The coolers are also designed for efficient operation with low air approach temperature and low pressure drop. The water separator efficiently separates the condensate from the compressed air. |

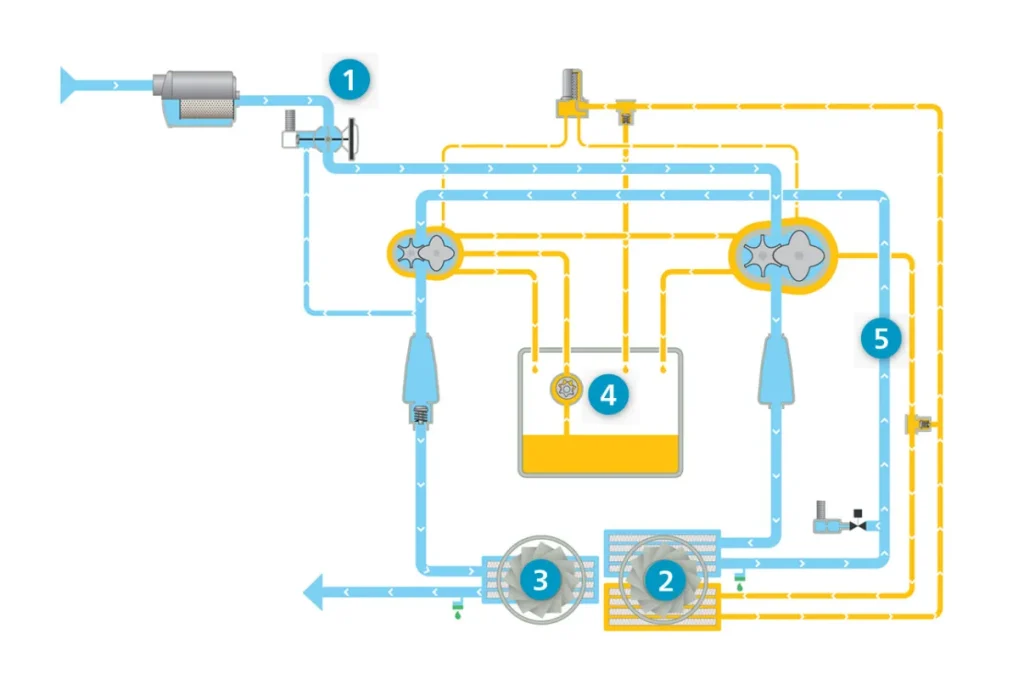

Oil and air flows: air-cooled (ZT)

| ①Filtration & first compression

The light blue flow represents the air. Air is drawn into the compressor through the inlet filter, where it is cleaned. It then passes through the throttle valve with integrated blow off valve, which takes care of the load/unload regulation. In the first compression stage the air pressure is raised to the intermediate pressure, after which the air is cooled down in the intercooler. |

④Oil flow

The yellow flow is the oil path within the compressor. The oil pump sucks oil from the oil sump and pumps it through the oil cooler and a high efficiency filter to deliver cool, clean oil to the bearings and the gears. The oil then flows back to the gear casing. |

| ②Cooling & second compression After the intercooler, the air passes through a moisture separation system before entering the high pressure stage. In the high pressure stage the pressure is brought to the final pressure. |

⑤Water flow

The dark blue flow represents the water. Water is used in the oil cooler, the intercooler, and the aftercooler, as well as in the integrated dryer. |

| ③Cooling & drying The air at the outlet of the high pressure stage is split into two parts. One part goes via the pulsation damper with integrated check valve to the aftercooler, where it is cooled down and moisture is separated and evacuated. A second part goes directly to the regeneration area of the heat compression MD dryer.In the regeneration area of the dryer the hot air regenerates the adsorption drum before passing through the regeneration cooler, where it is cooled down and moisture is separated and evacuated. The cold air coming from the regeneration section is then mixed with the cold air from the aftercooler in the nozzle ejector system before passing through the drying section of the adsorption drum where the moisture is removed. Dry air leaves the compressor through the outlet connection flanges. |

Technical Specifications

ZT 110-160 Technical Specifications

| Type | Working pressure (1) | Free Air Delivery (2) | Installed motor power (3) | Noise level (4) | |

| bar(e) | l/s | m³/min | kW | dB(A) | |

| ZT 110 – 7.5 | 7.5 | 315 | 18.9 | 110 | 79 |

| ZT 110 – 8.6 | 8.6 | 294 | 17.7 | ||

| ZT 110 – 10 | 10 | 274 | 16.5 | ||

| ZT 132 – 7.5 | 7.5 | 360 | 21.6 | 132 | |

| ZT 132 – 8.6 | 8.6 | 335 | 20.1 | ||

| ZT 132 – 10 | 10 | 311 | 18.7 | ||

| ZT 145 – 7.5 | 7.5 | 390 | 23.4 | 145 | |

| ZT 145 – 8.6 | 8.6 | 361 | 21.6 | ||

| ZT 145 – 10 | 10 | 348 | 20.9 | ||

| ZT 160 – 7.5 | 7.5 | 431 | 25.8 | 160 | |

| ZT 160 – 8.6 | 8.6 | 415 | 24.9 | ||

| ZT 160 – 10 | 10 | 396 | 23.7 | ||

ZT 110-160 VSD Technical Specifications

| Type | Working pressure (1) | Free Air Delivery (2) | Installed motor power (3) | Noise level (4) | ||

| bar(e) | l/s | m³/min | kW | dB(A) | ||

| ZT 110 VSD – 8.6 | Minimum | 4 | 101-320 | 6.0-19.2 | 110 | 79 |

| Effective | 7 | 100-320 | ||||

| Maximum | 8.6 | 99-299 | 5.9-17.9 | |||

| ZT 110 VSD – 10.4 | Minimum | 6.5 | 166-292 | 10-17.5 | ||

| Effective | 9 | 165-267 | 9.9-17.5 | |||

| Maximum | 10.4 | 192-267 | 11.5-16.6 | |||

| ZT 132 VSD – 8.6 | Minimum | 4 | 125-358 | 7.5-21.5 | 132 | |

| Effective | 7 | 125-357 | 7.5-21.4 | |||

| Maximum | 8.6 | 125-337 | 7.5-20.2 | |||

| ZT 132 VSD – 10.4 | Minimum | 6.5 | 165-331 | 9.9-19.9 | ||

| Effective | 9 | |||||

| Maximum | 10.4 | 192-316 | 11.5-19.0 | |||

| ZT 160 VSD – 8.6 | Minimum | 4 | 144-410 | 8.7-24.6 | 160 | |

| Effective | 7 | 8.6-24.6 | ||||

| Maximum | 8.6 | 144-385 | 8.6-23.0 | |||

| ZT 160 VSD – 10.4 | Minimum | 6.5 | 165-378 | 9.9-22.7 | ||

| Effective | 9 | |||||

| Maximum | 10.4 | 191-361 | 11.5-21.6 | |||

Dimensions

| Type | L | W | H | Weight |

| mm | kg | |||

| Air cooled | Air cooled | Air cooled | Air cooled | Air cooled |

| ZT 110-160 (VSD) | 3400 | 1660 | 2150 | 3850 |

| ZT 110-160 (VSD) FF iMD | 4085 | 4250 | ||

(1)For the FF variant, please consult Atlas Copco.

(2)Unit performance measured according to ISO 1217, Annex C & E, Edition 4 (2009). Reference conditions: absolute inlet pressure 1 bar (14.5 psi) / intake air temperature 20°C (68°F). Free Air Delivery (FAD) is measured at maximum working pressure (or effective working pressure for VSD variants).

(3)The installed motor power might deviate depending on the options, voltages and pressure variants.

(4)A-weighted emission sound pressure level at the work station (LpWSAd). Measured according to ISO 2151: 2008 using ISO 9614-2 (sound intensity scanning method). ZT variants including ducting on the outlet grating of cooling air. The added correction factor (± 3 dB(A)) is the total uncertainty value (KpAd) conform with the test code.

Brochure

If you need Atlas Copco ZR 110-160 VSD (FF) Oil-free Compressors brochure, please click the link below to view or download it.

Atlas Copco ZR ZT 110-160 (VSD) FF Oil-free Rotary Screw Air Compressors

| Weight | 3850 kg |

|---|---|

| Dimensions | 340 × 166 × 215 cm |

| 1-9 Pcs | $20000.00 |

| ≥10 Pcs | $15000.00 |

| Country of Origin | CN |

| Delivery Time | 60-90 Days |

| MOQ | 1 Piece |

| Packing | Wooden Crate |

| Product Quality | Brand-New Original |

| Transaction Mode | CFR, CIF, DAP, DDP, DPU, EXW, FCA, FOB |

Eris –

Satisfied cooperation with BOAO.

We purchased the Atlas Copco ZT 160 VSD oil-free rotary screw air compressor from BOAO Air Compressor Co., Ltd. for our food processing line. The air quality meets our strict hygiene requirements, and the pressure remains stable during continuous production. Noise levels are low, and energy consumption is noticeably better than our previous unit. BOAO provided professional guidance, timely delivery, and reliable after-sales support. The compressor has helped improve both efficiency and production safety in our factory.