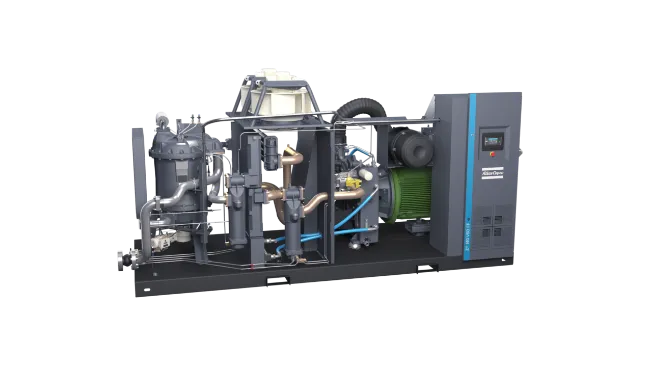

The Atlas Copco ZT 55-90 (VSD) (FF) Oil-free Air Compressor’s (ZT 55, ZT 75, ZT 90) superior oil-free screw elements provide the optimum combination of high Free Air Delivery (FAD) with the lowest energy consumption. Ample sized cooling, low pressure drops and an extremely efficient drive train result in the highest compressor package efficiency.

Class-leading compressed air products

With the ZR/ZT compressor, Atlas Copco provides a superior solution without hidden costs. The totally integrated, ready-to- use package includes internal piping, coolers, motor, lubrication and control system. The Full Feature version even integrates an IMD adsorption dryer for an impeccable end product. Installation is fault-free, commissioning time is low and no external instrument air is required. You simply plug and run.

| 1.Central controllers

Having a central controller reduces the average pressure band.It also reduces the operating pressure of your machines.

•By reducing the pressure by 1 bar (or 14.5 psi), your energy usage lowers by 7%.

•By reducing the pressure by 1 bar (or 14.5 psi) decreases air leakages by 13%.

Multiple embedded functions in the Optimizer 4.0 in which pressure, capacity and speed can be regulated. |

4.Ventilation

Compressors generate heat. Adequate evacuation of this heat will ensure favorable working conditions for compressors and dryers alike. |

| 2.Energy efficient and reliable compressors

All smart AIR solutions start with picking the correct components in the correct combination. Choosing energy efficient compressors, paying special attention to the mix of compressors will be a major contributor to a smart AIR solution. Our sound proof design contributes to a better working environment around the compressors. Our compressors have been designed with maintenance in mind, reducing the downtime of machines and improving availability of compressed air. |

5.Air receiver

Even with a Variable Speed Drive air compressor, having an appropriately sized buffer tank for compressed air will help smoothening the variation in demand and allow compressors to work in more stable operating conditions, thus helping both energy efficiency and reliability. |

| 3.Variable Speed Drive (VSD) compressors

Compressed air demand of most applications varies widely. Adding one or multiple VSD compressors to the installation will greatly help to improve energy efficiency of the total installation, stability of compressed air pressure and reliability, thanks to more stable regime of each machine. |

6.Compressed air dryers

The correct choice of dryer technology corresponding to the compressed air quality requirements is detrimental to a reliable and energy efficient compressed air installation.

The choice for integrated dryers – our full feature concept – will have additional benefits, reducing installation cost, time and complexity, having dryers controlled together with the compressors, reducing connecting pipes, hence the chance of leakages and extra pressure drops. And look at the major space saving full feature machines can bring.

Smart AIR solutions have impact on every aspect of your compressed air installation. |

| 7.Compressed air filters

Also the correct filter grade in correspondence with air quality requirements will be an important contributor in a smart AIR solution. This goes hand in hand with correct maintenance of the filters, as incorrectly maintained filters will jeopardize both the reliability of your installation as the energy efficiency. |

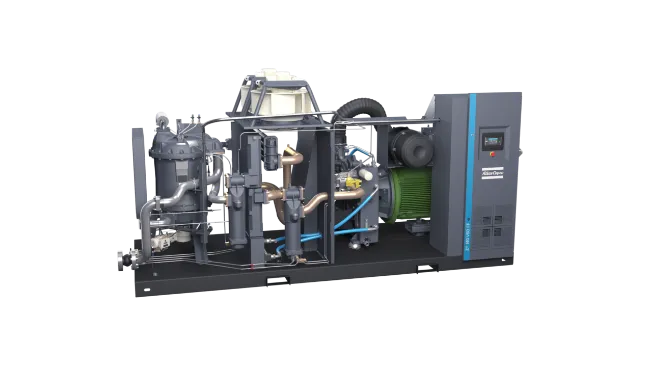

Design & control algorithms for optimal efficiency

With the Atlas Copco ZT 55-90 (VSD) (FF) oil-free air compressor, Atlas Copco provides a superior solution without hidden costs. The totally integrated, ready-to- use package includes internal piping, coolers, motor, lubrication and control system. The Full Feature version even integrates an IMD adsorption dryer for an impeccable end product. Installation is fault-free, commissioning time is low and no external instrument air is required. You simply plug and run.

|

Components designed for efficiency

●Compressor elements with superior coating, optimized design and low loss bearings and seals ensure highest efficiency.

●Efficient intake filtration for minimum losses and low pressure drop.

●Coolers are designed for efficiency with low pressure drop and low air approach temperature, ensuring coolest possible running conditions.

●Our fixed speed machines come with IE4 super premium efficiency motors, giving you extra energy savings, every hour the machine runs.

●VSD machines are equipped with IE3 premium efficiency motors, in combination with our highly efficient in-house designed Neos frequency converter.

●With machines typically running 4000 to 8000 hours per year, again a major contributor to energy savings. |

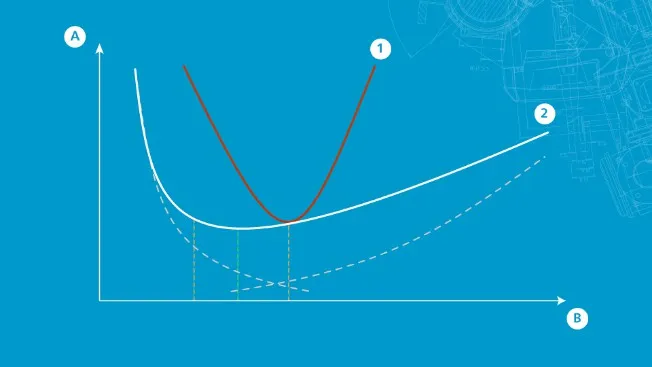

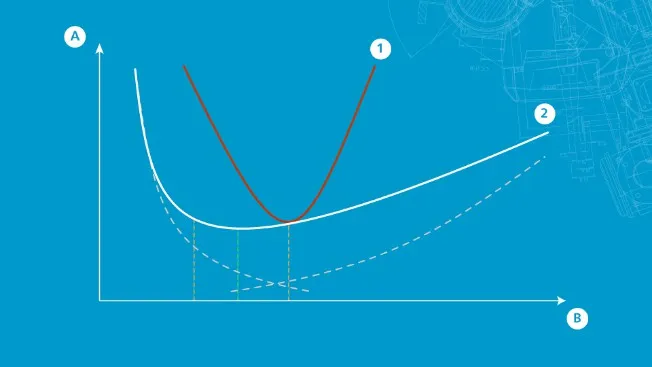

| Lower energy costs with Atlas Copco’s VSD technology

Over 80% of a compressor’s lifecycle cost is taken up by the energy it consumes. Moreover, the generation of compressed air can account for more than 40% of a plant’s total electricity bill. To cut your energy costs, Atlas Copco pioneered Variable Speed Drive (VSD) technology in the compressed air industry. VSD leads to major energy savings, while protecting the environment for future generations. Thanks to continual investments in this technology, Atlas Copco offers the widest range of integrated VSD compressors on the market.

Legend

A = Losses

B = Speed

1 = Total losses traditional element

2 = Total losses Atlas Copco element |

|

|

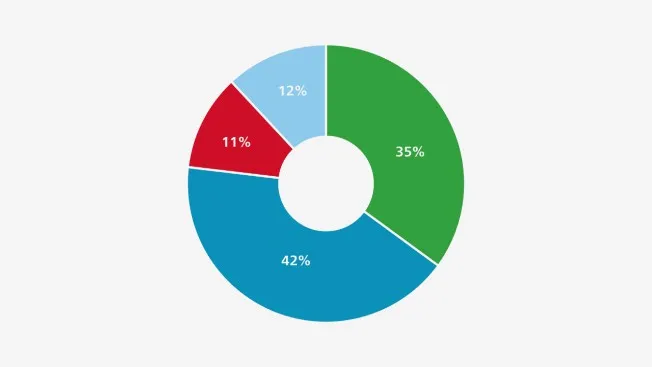

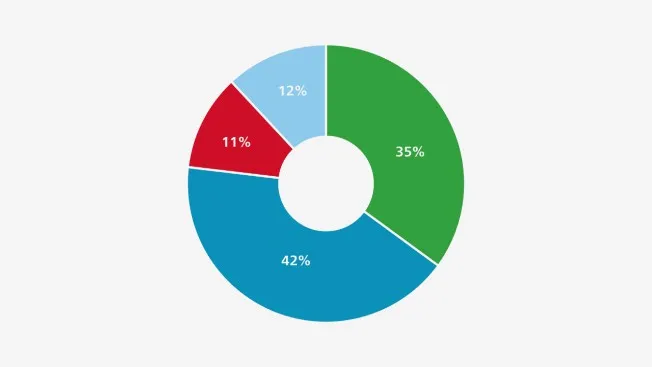

Up to 35% energy savings

Atlas Copco’s VSD technology closely follows the air demand by automatically adjusting the motor speed. This results in large energy savings of up to 35%. The Life Cycle Cost of a compressor can be cut by an average of 22%. In addition, lowered system pressure with VSD minimizes energy use across your production dramatically.

Legend

42% = Energy

35% = Energy savings with VSD

12% = Investment

11% = Maintenance |

| Monitor your compressed air installation with SMARTLINK

Knowing the status of your compressed air equipment at all times is the surest way to achieve optimal efficiency and maximum availability.

Go for energy efficiency

Customized reports on the energy efficiency of your compressor room.

Increase uptime

All components are replaced on time, ensuring maximum uptime.

Save money

Early warnings avoid breakdowns and production loss. |

|

|

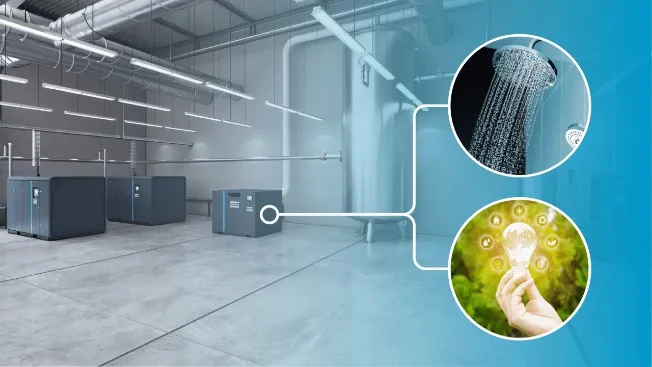

Energy Recovery

You can turn your compressor into an energy source. Our ZR compressors equipped with Energy Recovery can help you achieve your goals in becoming carbon neutral. Compressed air is one of the most important utilities for the industry. It is also one of the largest consumers of energy. Up to 94% of the electrical energy is converted into compression heat. Without energy recovery, this heat is lost into the atmosphere via the cooling system and radiation. You can use hot water recovered from the compressed air system for sanitary purposes and space heating. But it is particularly suitable for process applications.

Using the hot water as boiler pre-feed or directly in processes requiring 70 to 90°C can save you costly energy sources such as natural gas and heating oil. |

Optimize your system

With the ZR, Atlas Copco provides an all-in-one standard package incorporating the latest technology in a built to-last design. To further optimize your ZR/ZT’s performance or to simply tailor it to your specific production environment, optional features are available.

|

ZT 55-90 (VSD) |

| Monitoring & Protection bundle (Anti-Condensation heaters / Monitoring & Protection bundle (Anti-Condensation heaters / SPM equipment / PT 1000 in the windings & bearings) |

• |

| Integrated SMARTLINK |

• |

| Kit for purge of dry air during standstill |

• |

| Silicone-free rotor for dryer |

Standard scope |

| Anchor pads |

• |

| Wooden case protection packaging |

• |

| High ambient temperature version* |

• |

| Test certificate |

• |

| Witnessed performance test |

• |

| IT Network (VSD) |

• |

| Energy recovery |

• |

| Teflon free |

• |

| MD heater |

• |

| Hot air |

• |

| Water shutoff valve |

• |

• Optional

* Maximum intake/cooling air temperature is 50°C/122 °F for HAT versions. Please note the availability of the option depends on the chosen configuration.

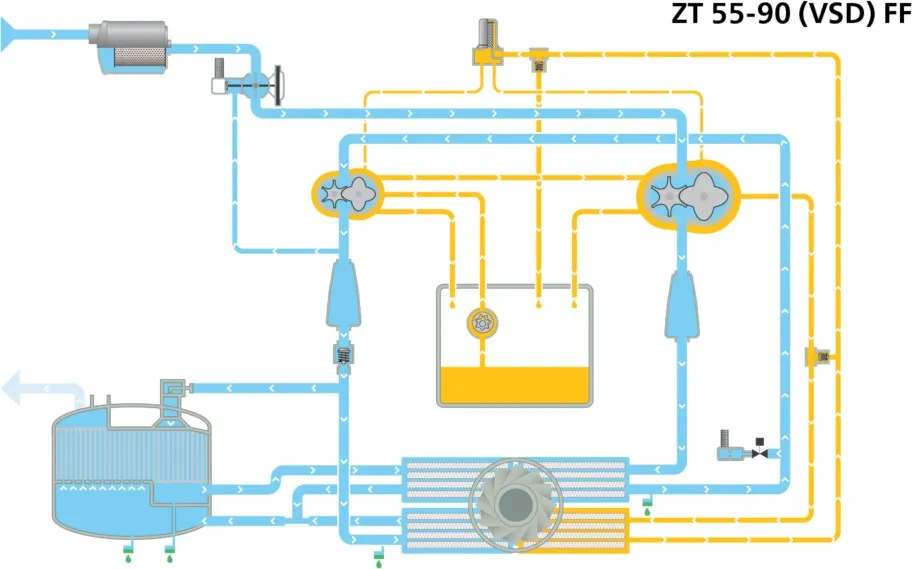

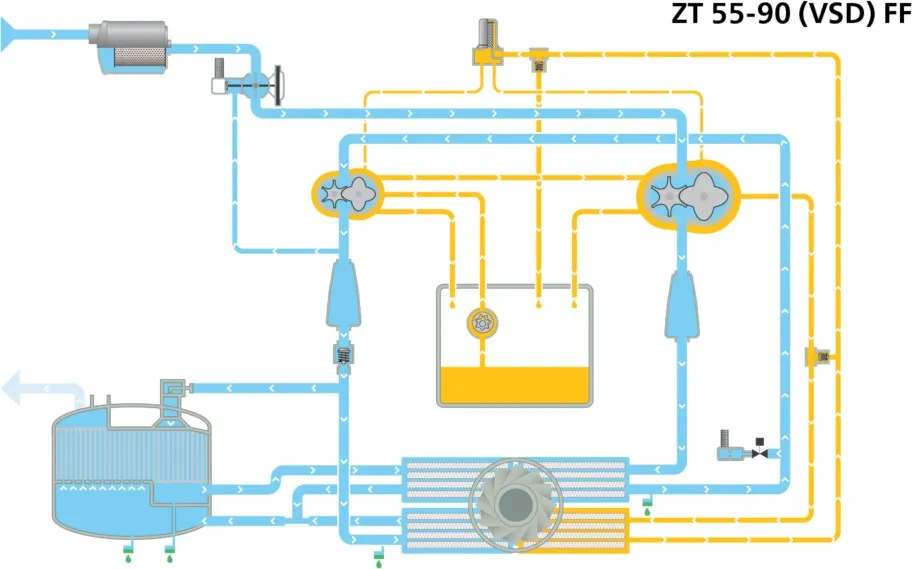

Atlas Copco ZT 55-90 (VSD) (FF) Oil-free Air Compressor Flowchart

Process flow, oil flow and cooling flow – step by step.

| 1. Filtration & first compression

The light blue flow represents the air. Air is drawn into the compressor through the inlet filter where the air is cleaned. Then passes through the throttle valve with integrated blow off valve that takes care of the load unload regulation. In the first compression stage the air pressure is raised to the intermediate pressure after which the air is cooled down in the inter-cooler. |

2. Cooling & second compression

After the inter-cooler the air passes through a moisture separation system before entering the high pressure stage. In the high pressure stage the pressure is brought to the final pressure. |

| 3. Cooling & drying

The air at the outlet of the high pressure stage is split in two parts. One part goes via the pulsation damper with integrated check valve to the after-cooler where it is cooled down and moisture is separated and evacuated. A second part goes directly to the regeneration area of the heat compression MD dryer.In the regeneration area of the dryer the hot air regenerates the adsorption drum after which it passes through the regeneration cooler where it is cooled down and moisture is separated and evacuated. The cold air coming from the regeneration section is then mixed with the cold air from the after-cooler in the nozzle-ejector system before passing through the drying section of the adsorption drum where the moisture is removed. Dry air leaves the compressor through the outlet connection flanges. |

4. Oil flow

The yellow flow is the oil path within the compressor where the oil pump sucks oil from the oil sump and pumps it through the oil cooler and a high efficiency filter to give cool clean oil to the bearings and the gears; then the oil flows back to the gear casing. |

Technical Specifications

ZT 55-90 (FF) Technical Specifications 50Hz

| Type |

Working pressure (1) |

Free Air Delivery (2) |

Installed motor power (3) |

Noise level (4) |

|

bar(e) |

l/s |

m³/min |

kW |

dB(A) |

| ZT 55 |

Minimum |

7.5 |

166.3 |

10 |

55 |

76 |

| Effective |

8.6 |

153 |

9.2 |

75 |

| Maximum |

10 |

137.4 |

8.2 |

76 |

| ZT 75 |

Minimum |

7.5 |

221.2 |

13.3 |

75 |

78 |

| Effective |

8.6 |

211.4 |

12.7 |

| Maximum |

10 |

201.5 |

12.1 |

74 |

| ZT 90 |

Minimum |

7.5 |

263.9 |

15.8 |

90 |

79 |

| Effective |

8.6 |

247.4 |

14.8 |

77 |

| Maximum |

10 |

233 |

14 |

79 |

ZT 55-90 (FF) Technical Specifications 60Hz

| Type |

Working pressure (1) |

Free Air Delivery (2) |

Installed motor power (3) |

Noise level (4) |

|

bar(e) |

l/s |

m³/min |

kW |

dB(A) |

| ZT 55 |

Effective |

8.6 |

158.4 |

9.5 |

55 |

77 |

| Maximum |

10 |

139.3 |

8.4 |

79 |

| ZT 75 |

Effective |

8.6 |

222.8 |

13.4 |

75 |

| Maximum |

10 |

197 |

11.8 |

76 |

| ZT 90 |

Effective |

8.6 |

258.7 |

15.5 |

90 |

78 |

| Maximum |

10 |

237.4 |

14.2 |

ZT 75-90 VSD (FF) Technical Specifications

| Type |

Working pressure (1) |

Free Air Delivery (2) |

Installed motor power (3) |

Noise level (4) |

|

bar(e) |

l/s |

m³/min |

kW |

dB(A) |

| ZT 75 VSD – 8.6 |

Minimum |

4 |

72.2 – 236.1 |

4.33 – 14.2 |

75 |

78 |

| Effective |

7 |

71.2 – 226.0 |

4.27 – 13.6 |

| Maximum |

8.6 |

70.7 – 205.2 |

4.24 – 12.3 |

| ZT 75 VSD – 10.4 |

Minimum |

6 |

79.2 – 235.8 |

4.8 – 14.1 |

76 |

| Effective |

9 |

78.2 – 199.6 |

4.7 – 12.0 |

| Maximum |

10.4 |

77.8 – 181.3 |

4.67 – 10.9 |

| ZT 90 VSD – 8.6 |

Minimum |

4 |

71.7 – 293.9 |

4.3 – 17.6 |

90 |

78 |

| Effective |

7 |

70.6 – 279.1 |

4.24 – 16.7 |

| Maximum |

8.6 |

70.1 – 254.7 |

4.2 – 15.3 |

| ZT 90 VSD – 10.4 |

Minimum |

6 |

73.0 – 289.5 |

4.4 – 17.4 |

77 |

| Effective |

9 |

72.0 – 247.1 |

4.3 – 14.8 |

| Maximum |

10.4 |

71.5 – 225.7 |

4.29 – 13.5 |

Brochure

If you need Atlas Copco ZT 55-90 (VSD) (FF) oil-free rotary screw air compressors brochure, please click the link below to view or download it.

Atlas Copco ZR ZT 55-90 (VSD) (FF) oil-free rotary screw air compressors

Inquiry Now

Anonymous_buyer –

BOAO handled delivery professionally and provided helpful startup guidance.

We purchased the Atlas Copco ZT 55 oil-free air compressor from BOAO Air Compressor Co., Ltd. for daily production use. The machine runs quietly, delivers clean air consistently, and maintains stable pressure during continuous operation. Energy usage is lower than expected, and maintenance has been minimal so far.