Atlas Copco ZR 200-355 VSD⁺ Oil-free Air Compressors

$20,000.00

High-efficiency Atlas Copco ZR 200-355 VSD⁺ Oil-free Air Compressors (ZR 200 VSD⁺, ZR 250 VSD⁺, ZR 315 VSD⁺, ZR 355 VSD⁺). Engineered using innovative in-house technology, the ZR oil-free air compressors are the result of years of research and development.

High-efficiency Atlas Copco ZR 200-355 VSD⁺ (ZR 200 VSD⁺, ZR 250 VSD⁺, ZR 315 VSD⁺, ZR 355 VSD⁺) Oil-free Air Compressor. Engineered using innovative in-house technology, the ZR oil-free air compressors are the result of years of research and development.

Contents

Atlas Copco ZR 200-355 VSD⁺ Oil-free Air Compressors Features & benefits

Introducing the Atlas Copco ZR 200-355 VSD⁺, where efficiency meets reliability and sustainability. This air compressor is designed for industries demanding high compressed air quality standards.

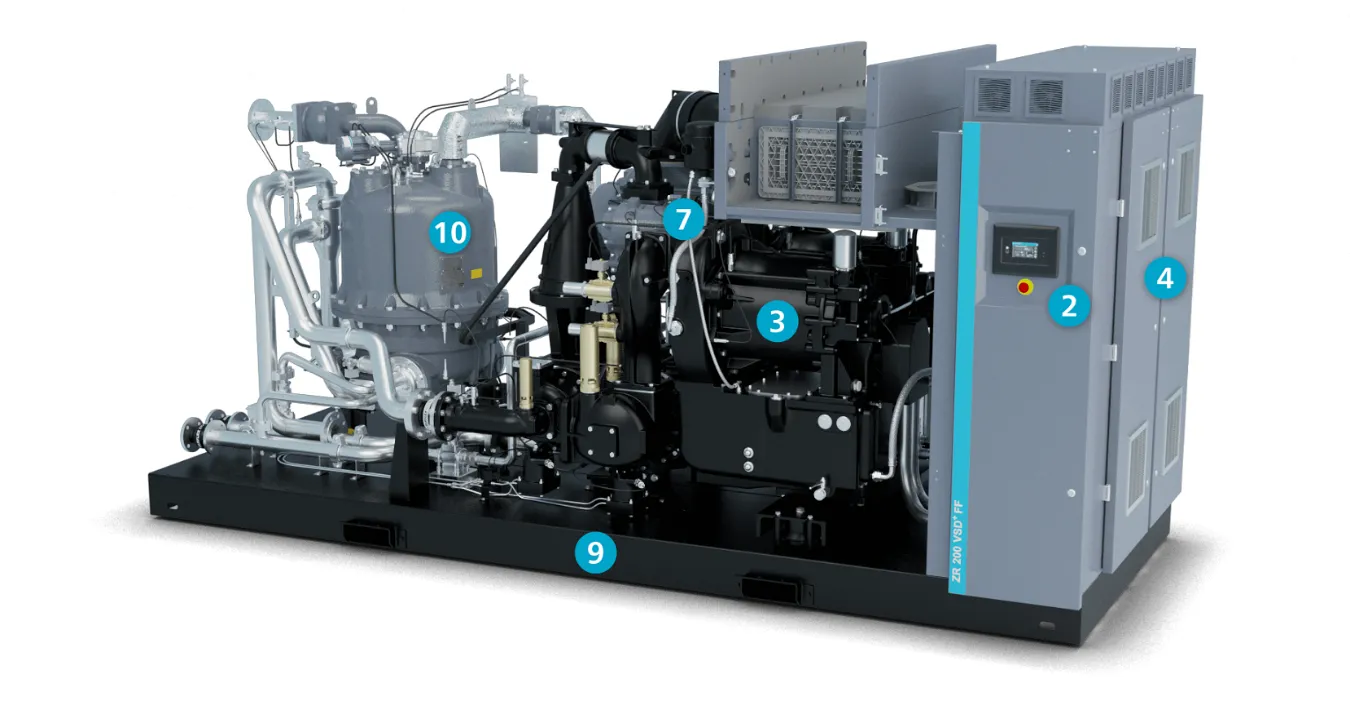

ZR 200-355 VSD⁺ FF (iMD)

LEFT VIEW LEFT VIEW |

RIGHT VIEW RIGHT VIEW |

| ①High performance elements ●Next generation world class compression element. ●Atlas Copco superior rotor coating for high durability. ●Thermal efficiency reduces the expansion leading to reduced wear and increased reliability. ●More compact, improved rotor profiles and cooling jackets for maximum durability. |

⑥Zero loss drains ●Clearance of all water & contamination. ●Increasing both product & system reliability. |

| ②Advanced touch screen monitoring system ●User-friendly Elektronikon® Touch, with enhanced connectivity potential. ●Included warning indications, maintenance scheduling and online visualization of the machine’s condition for increased reliability. |

⑦Easy access ●Easy access to all components to minimize maintenance times. ●Hinged doors for easy routine maintenance eg. cleaning. ●Saves valuable and often expensive floor space in a facility. ●Highest ratio flow/footprint on the market. |

| ③Efficient motor ●Permanent Magnet water cooled motor with oil lubricated bearings. ●Rock-solid reliability prevents dust and water entering the motor. |

⑧Easy access ●Easy access to all components to minimize maintenance times. ●Hinged doors for easy routine maintenance eg. cleaning. ●Saves valuable and often expensive floor space in a facility. ●Highest ratio flow/footprint on the market. |

| ④NEOS drive ●Atlas Copco NEOS inverter is designed to work in the harsh conditions of the compressor house. ●Modular design allows replacement of individual components, reducing maintenance cost. ●The cubicle keeps the inverter cool extending the lifetime & increasing operational efficiency. |

⑨Grouped service items ●Minimal service time because service parts are grouped together for ease of access. ●All components are designed for serviceability and long lasting lifetime. |

| ⑤Reliable cooling ●Cooler with highly efficient water separator for higher reliability. ●Stainless steel enlarged surface coolers to ensure top performance over a long lifetime. ●Pipes with star profile form bi-anodised aluminium for preventing corrosion ●Easily removable for quick, cost-efficient maintenance. |

⑩Integrated dryer ●Having an integrated dryer helps for easier installation, less pressure drop because of more efficient connections ●On top of that it also saves a lot of space in your compressor room. |

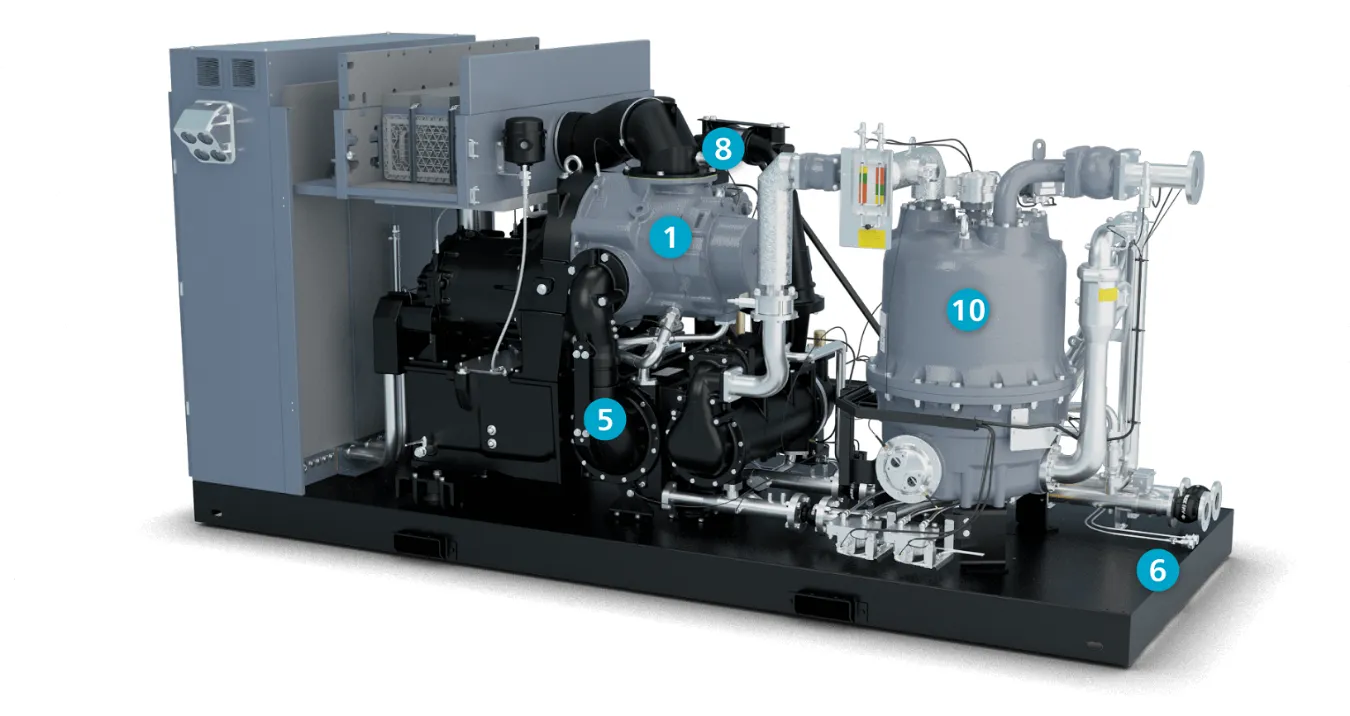

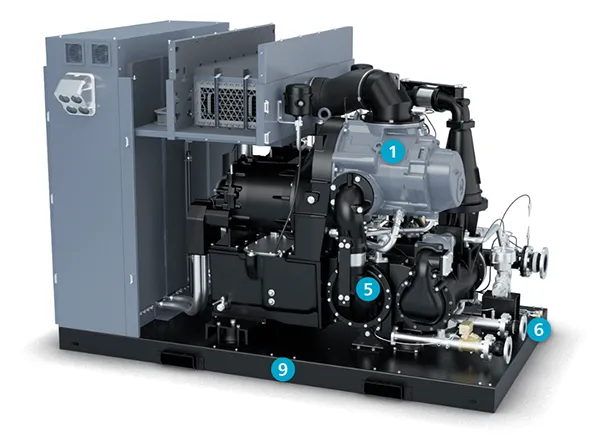

ZR 200-355 VSD⁺ FF (iMDG)

ZR 200-355 VSD⁺ FF (iMDG) RIGHT VIEW ZR 200-355 VSD⁺ FF (iMDG) RIGHT VIEW |

ZR 200-355 VSD⁺ FF (iMDG) LEFT VIEW ZR 200-355 VSD⁺ FF (iMDG) LEFT VIEW |

| ①High performance elements ●Next generation world class compression element. ●Atlas Copco superior rotor coating for high durability. ●Thermal efficiency reduces the expansion leading to reduced wear and increased reliability. ●More compact, improved rotor profiles and cooling jackets for maximum durability. |

⑥Zero loss drains ●Clearance of all water & contamination. ●Increasing both product & system reliability. |

| ②Advanced touch screen monitoring system ●User-friendly Elektronikon® Touch, with enhanced connectivity potential. ●Included warning indications, maintenance scheduling and online visualization of the machine’s condition for increased reliability. |

⑦Easy access ●Easy access to all components to minimize maintenance times. ●Hinged doors for easy routine maintenance eg. cleaning. ●Saves valuable and often expensive floor space in a facility. ●Highest ratio flow/footprint on the market. |

| ③Efficient motor ●Permanent Magnet water cooled motor with oil lubricated bearings. ●Rock-solid reliability prevents dust and water entering the motor. |

⑧Soundproof design ●Silenced canopy ensures optimal working conditions for everyone in the immediate environment. ●Optimized internal ducting and integrated pulsation damper to reduce the noise level. ●High quality coated canopy to prevent dust. |

| ④NEOS drive ●Atlas Copco NEOS inverter is designed to work in the harsh conditions of the compressor house. ●Modular design allows replacement of individual components, reducing maintenance cost. ●The cubicle keeps the inverter cool extending the lifetime & increasing operational efficiency. |

⑨Grouped service items ●Minimal service time because service parts are grouped together for ease of access. ●All components are designed for serviceability and long lasting lifetime. |

| ⑤Reliable cooling ●Cooler with highly efficient water separator for higher reliability. ●Stainless steel enlarged surface coolers to ensure top performance over a long lifetime. ●Pipes with star profile form bi-anodised aluminium for preventing corrosion ●Easily removable for quick, cost-efficient maintenance. |

⑩Dryer |

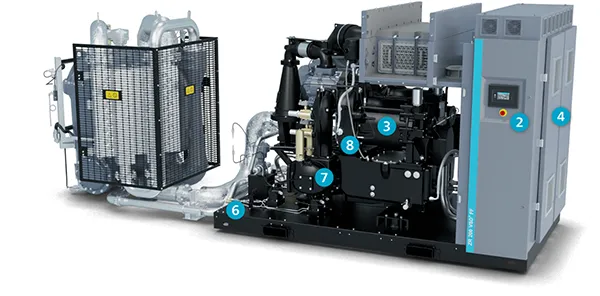

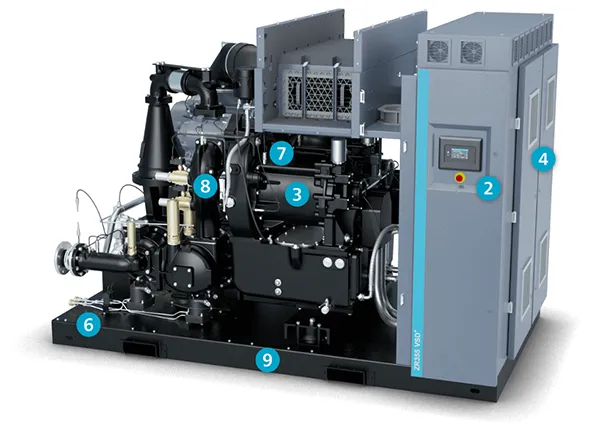

ZR 200-355 VSD⁺ PACK

|

|

| ①High performance elements ●Next generation world class compression element. ●Atlas Copco superior rotor coating for high durability. ●Thermal efficiency reduces the expansion leading to reduced wear and increased reliability. ●More compact, improved rotor profiles and cooling jackets for maximum durability. |

⑥Zero loss drains ●Clearance of all water & contamination. ●Increasing both product & system reliability. |

| ②Advanced touch screen monitoring system ●User-friendly Elektronikon® Touch, with enhanced connectivity potential. ●Included warning indications, maintenance scheduling and online visualization of the machine’s condition for increased reliability. |

⑦Easy access ●Easy access to all components to minimize maintenance times. ●Hinged doors for easy routine maintenance eg. cleaning. ●Saves valuable and often expensive floor space in a facility. ●Highest ratio flow/footprint on the market. |

| ③Efficient motor ●Permanent Magnet water cooled motor with oil lubricated bearings. ●Rock-solid reliability prevents dust and water entering the motor. |

⑧Soundproof design ●Silenced canopy ensures optimal working conditions for everyone in the immediate environment. ●Optimized internal ducting and integrated pulsation damper to reduce the noise level. ●High quality coated canopy to prevent dust. |

| ④NEOS drive ●Atlas Copco NEOS inverter is designed to work in the harsh conditions of the compressor house. ●Modular design allows replacement of individual components, reducing maintenance cost. ●The cubicle keeps the inverter cool extending the lifetime & increasing operational efficiency. |

⑨Grouped service items ●Minimal service time because service parts are grouped together for ease of access. ●All components are designed for serviceability and long lasting lifetime. |

| ⑤Reliable cooling ●Cooler with highly efficient water separator for higher reliability. ●Stainless steel enlarged surface coolers to ensure top performance over a long lifetime. ●Pipes with star profile form bi-anodised aluminium for preventing corrosion ●Easily removable for quick, cost-efficient maintenance. |

Optimize your system

With the ZR 200-355 VSD+ , Atlas Copco provides an all-in-one standard package incorporating the latest technology -in a built-to-last design. To further optimize your ZR’s performance or to simply tailor it to your specific production environment, optional features are available.

| ZR 200-355 VSD⁺ | |

| Anchor pads | • |

| Energy recovery | • |

| Silicone-free rotor | • |

| High ambient temperature version | • |

| Kit for purge of dry air during standstill | • |

| IT network | • |

| Wooden case protection packaging | • |

| Test certificate | • |

| Witnessed performance test | • |

Please note that the availability of the option depends on the chosen configuration.

With a dedicated customization team, we can further tailor our units to your requirements.

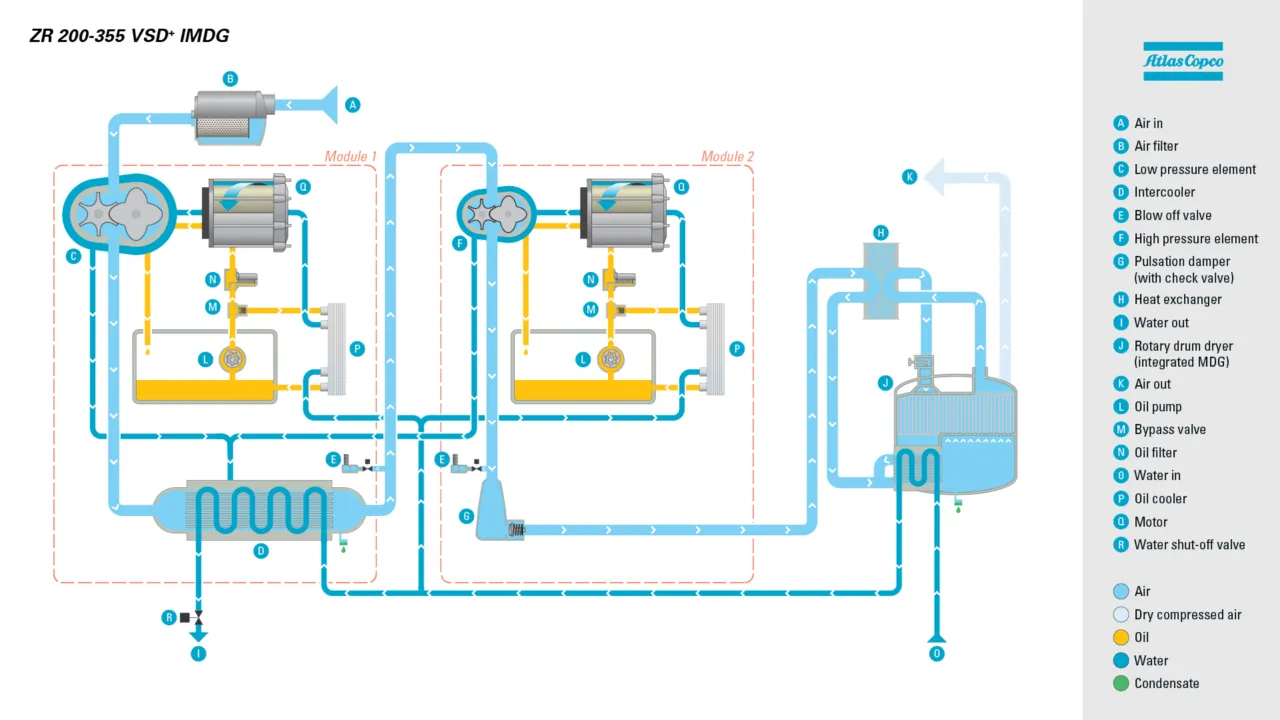

Atlas Copco ZR 200-355 VSD⁺ Oil-free Air Compressors Flowchart

| Filtration & compression The air is drawn into the compressor through the inlet filter where the air is cleaned. It then continues to the first compression stage where the air is compressed to an intermediate pressure. |

Heat exchanger 40% of the dry air goes into the heat exchanger, where it picks up the heat from the incoming hot wet compressed air. This dry and hot regeneration air enters the regeneration section of the drum, which passes through the regeneration cooler where it is cooled down and moisture is separated and drained. Afterwards it is mixed with the incoming cooled wet compressed air. |

| Cooling & second compression After the first compression, the air is cooled down in the intercooler. Once the air is cooled down, it passes through a moisture separation system before entering the high-pressure stage. In the high-pressure stage, the pressure is brough to its final pressure. |

Oil The yellow lines represent the oil flow of the compressor. Oil is pumped from the reservoir through a high efficiency filter to provide clean, cooled oil to the gears for lubrication. Afterwards the oil flows back into the reservoir. There is also a bypass valve that allows the oil to flow to the oil cooler, so the optimal temperature is guaranteed, increasing efficiency and durability of the components. |

| Exchanging heat & cooling The hot wet compressed air at the outlet of the high-pressure stage goes through the pulsation damper with integrated check valve to the heat exchanger. Here it transfers the heat to the integrated dryer used further in the process. The air continues to the aftercooler where it is cooled down and the poisture gets separated and drained. |

Water The dark blue lines represent the water flow. Cooling water is brought into the cycle and splits towards both modules and the dryer. First of all, the cooling water is directed to the integrated dryer. Secondly, the water goes to both the inter- and aftercooler te reduce the temperatie of the compressed air. Lastly, the water splits to the oil coolers to reduce the temperature of the oil. It then passes through the jackets of the motor and elements to guarantee an optimal temperature. The water continues back to the cooler and is directed further to the water outlet. |

| Integrated dryer The cooled wet compressed air is now mixed with 40% of the cooled regeneration air and enters the dryer. The dry compressed air with guaranteed dew point is now ready for use in your application. |

Technical specifications

Specifications ZR 200-355 VSD⁺ Pack

| Model | Working pressure | Free Air Delivery (1) | Installed power | Noise level (2) | Weight | |||

| bar(e) | l/s | m³/min | kW | Motor Specifications | dB(A) | kg | ||

| ZR 200 VSD⁺ 10.4 | Minimum | 4 | 210 – 696 | 12.6 – 41.8 | 200 | 2 x 100 | 72 | 5439 |

| Effective | 7 | 210 – 658 | 12.6 – 39.5 | |||||

| Maximum | 10.4 | 208 – 528 | 12.5 – 31.7 | |||||

| ZR 250 VSD⁺ 10.4 | Minimum | 4 | 210 – 846 | 12.6 – 50.8 | 250 | 2 x 125 | 73 | |

| Effective | 7 | 210 – 806 | 12.6 – 48.4 | |||||

| Maximum | 10.4 | 208 – 668 | 12.5 – 40.1 | |||||

| ZR 315 VSD⁺ 10.4 | Minimum | 4 | 210 – 974 | 12.6 – 58.5 | 315 | 2 x 160 | ||

| Effective | 7 | |||||||

| Maximum | 10.4 | 208 – 838 | 12.5 – 50.3 | |||||

| ZR 355 VSD⁺ 8.6 | Minimum | 4 | 210 – 1084 | 12.6 – 65.1 | 355 | 2 x 180 | ||

| Effective | 7 | 12.6 – 65.0 | ||||||

| Maximum | 8.6 | 209 – 1014 | 12.5 – 60.8 | |||||

| ZR 355 VSD⁺ 10.4 | Minimum | 4 | 210 – 1014 | 12.6 – 60.8 | ||||

| Effective | 7 | |||||||

| Maximum | 10.4 | 208 – 935 | 12.5 – 56.1 | |||||

Specifications ZR 200-355 VSD⁺ Pack

| Model | Working pressure | Free Air Delivery (1) | Installed power | Motor specifications | Noise level (2) dB(A) |

Weight | ||

| psig | l/s | cfm | hp | lb | ||||

| ZR 200 VSD⁺ 10.4 | Minimum | 58 | 210 – 696 | 445 – 1474 | 268 | 2 x 134 | 72 | 11991 |

| Effective | 100 | 210 – 658 | 445 – 1394 | |||||

| Maximum | 150 | 208 – 528 | 441 – 1118 | |||||

| ZR 250 VSD⁺ 10.4 | Minimum | 58 | 210 – 846 | 445 – 1792 | 335 | 2 x 168 | 73 | |

| Effective | 100 | 210 – 806 | 445 – 1707 | |||||

| Maximum | 150 | 208 – 668 | 441 – 1415 | |||||

| ZR 315 VSD⁺ 10.4 | Minimum | 58 | 210 – 974 | 445 – 2064 | 422 | 2 x 215 | ||

| Effective | 100 | |||||||

| Maximum | 150 | 208 – 838 | 441 – 1775 | |||||

| ZR 355 VSD⁺ 8.6 | Minimum | 58 | 210 – 1084 | 445 – 2297 | 476 | 2 x 241 | ||

| Effective | 100 | 444 – 2296 | ||||||

| Maximum | 150 | 209 – 1014 | 443 – 2147 | |||||

| ZR 355 VSD⁺ 10.4 | Minimum | 58 | 210 – 1014 | 445 – 2147 | ||||

| Effective | 100 | |||||||

| Maximum | 150 | 208 – 935 | 441 – 1980 | |||||

Dimensions ZR 200-355 VSD⁺ Pack

| Model | Length | Width | Height |

| mm | |||

| ZR 200-355 VSD⁺ Pack | 3044 | 1760 | 2150 |

Dimensions ZR 200-355 VSD⁺ Pack

| Model | Length | Width | Height |

| inch | |||

| ZR 200-355 VSD⁺ Pack | 120 | 69 | 85 |

(1)Unit performance measured according to ISO 1217, Annex E, Edition 4 (2009).

Reference conditions:

–Relative humidity 0%

–Absolute inlet pressure 1 bar (14.5 psi)

–Intake air temperature 20°C (68°F)

Free Air Delivery (FAD) is measured at effective working pressure.

(2)A-weighted emission sound pressure level at the work station (LpWSAd). Measured according to ISO 2151:2008 using ISO 9614-2 (sound intensity scanning method). The added correction factor (+/- 3 db(A)) is the total uncertainty value (KpAd) conform with the test code.

Brochure

If you need Atlas Copco ZR 200-355 VSD⁺ Oil-free Air Compressors brochure, please click the link below to view or download it.

| Weight | 7700 kg |

|---|---|

| Dimensions | 534.8 × 175.4 × 220 cm |

| 1-9 Pcs | $20000.00 |

| ≥10 Pcs | $15000.00 |

| Country of Origin | CN |

| Certificate | ISO 8573-1 CLASS 0 |

| Delivery Time | 60-90 Days |

| MOQ | 1 Piece |

| Packing | Wooden Crate |

| Product Quality | Brand-New Original |

| Transaction Mode | CFR, CIF, DAP, DDP, DPU, EXW, FCA, FOB |

Jim –

A crucial investment paying daily dividends.

We installed the Atlas Copco ZR 355 VSD⁺ from BOAO Air Compressor Co., Ltd. The upgrade is phenomenal. The VSD⁺ drive immediately cut our specific energy consumption by over 30% compared to the old unit—measurable savings on day one. The Class 0 air quality is guaranteed, which is non-negotiable for our product safety. The machine runs quieter than expected for its size and holds pressure perfectly. BOAO provided seamless installation logistics and expert technical support. A crucial investment paying daily dividends.