Atlas Copco ZR 55-90 (VSD) (FF) Oil-free Air Compressor

$20,000.00

The Atlas Copco Atlas Copco ZR 55-90 (VSD) (FF) oil-free air Compressors (ZR 55, ZR75, ZR90) are designed for industries that demand absolute air purity, energy efficiency, and long-term reliability.

The Atlas Copco Atlas Copco ZR 55-90 (VSD) (FF) oil-free air Compressors (ZR 55, ZR75, ZR90) are designed for industries that demand absolute air purity, energy efficiency, and long-term reliability. Built on Atlas Copco’s proven oil-free compression technology, these compressors deliver 100% oil-free air in compliance with the most stringent quality standards. With flexible configurations, including Variable Speed Drive (VSD) and Full-Feature (FF) options, the ZR/ZT 55–90 series provides stable performance while minimizing operating costs, making it an ideal solution for continuous industrial applications.

Contents

Having the right air quality protects your production

Compressed air is used in a wide variety of manufacturing and commercial operations. Air is generated from the ambient atmosphere around the compressor and typically would contain contaminants in the form of dust and water which are two naturally occurring impurities while a third impurity which is oil typically gets added to compressed air due to the compression process. Oil though can be avoided/eliminated by using our 100% oil-free compressors.

|

|

| 100% oil-free compressed air

For over 60 years Atlas Copco has pioneered the development of oil-free air technology. Resulting in the largest range of air compressors and blowers within our industry. Through continuous research and development, we achieved a new milestone, setting the standard for air purity as the first manufacturer to be awarded ISO 8573-1 CLASS 0 certification. CLASS 0 certification means zero risk of oil contamination from our products. |

Air treatment

Untreated compressed air contains moisture and possibly dirt particles that can damage your air system and contaminate your end product. The resulting maintenance costs far exceed air treatment costs. Atlas Copco believes in effective prevention and provides a complete range of air treatment solutions to protect investments, equipment, production processes and end products. |

|

|

| Avoid downtime

Low quality air heightens the risk of corrosion, which can lower the life span of production equipment. The air treatment solutions produce clean air that enhances your system’s reliability, avoiding costly downtime and production delays. Compressed air coming into contact with your final products should not affect their quality. Atlas Copco provides clean, dry air to protect your production and reputation in the market. |

ISO 22000

ISO 22000 is a management system for food safety. Atlas Copco is among a few compressor manufacturers to have their oil free air compressors and related dryers and filters certified for ISO 22000 by Lloyds Register Quality Assurance. |

The highest reliability

ZR 90 VSD

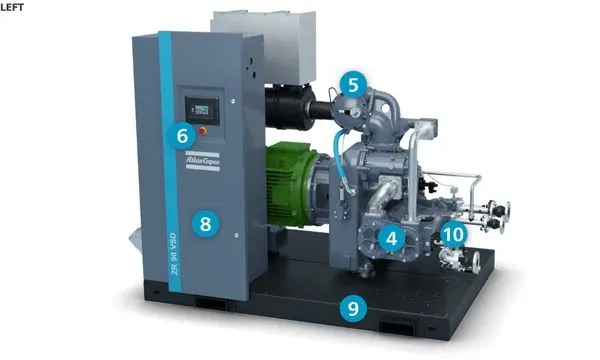

ZR 90 VSD LEFT VIEW ZR 90 VSD LEFT VIEW |

ZR 90 VSD RIGHT VIEW ZR 90 VSD RIGHT VIEW |

| 1.Oil-free air compressor elements (Class 0) • Unique seal design guarantees certified oil-free air • Superior coating for high durability • Cooling jackets to ensure world class compression in different conditions |

2.Main drive motor • IP55 TEFC motor protects against dust, chemicals and humidity • Continuous operation under severe ambient conditions |

| 3.Efficient intake air filtration • 2 stage dust removal system (99.9% for 3 micron) • High grade protection of the compressor |

4.Highly reliable coolers • Compact design with low approach temperature • Low thermal stresses ensure long lifetime • Reliable water separation ensures low water carry over to downstream equipment • Stainless steel water coolers designed for durability and easy serviceability |

| 5.Reliable load/unload regulation • No external air supply needed • Mechanical interlock of inlet and blow-off valve • Low unload power |

6.Advanced touch screen monitoring system • User friendly Elektronikon Touch with enhanced connectivity potential • Integrated smart algorithms to protect equipment in harsh conditions • Including warning indications, maintenance scheduling and online visualization of the machine’s condition |

| 7.Complete Plug-and-play package • All in one solution: fault free installation, easy commissioning and quick start up • Includes internal piping, coolers, motor, drive, lubrication and control system |

8.Sound proof design • Silenced canopy ensures optimal working conditions for everyone in the immediate environment • Optimized internal ducting and integrated pulsation damper to reduce noise level |

| 9.Ease of maintenance • Minimal service time with service parts grouped together for ease of access • All components are designed for serviceability and longevity • Optional service plans available to extend warranty |

10.Smart Energy Recovery valve • The Energy Recovery option on ZR has improved regulation to ensure stable water temperature at the required level for your processes. |

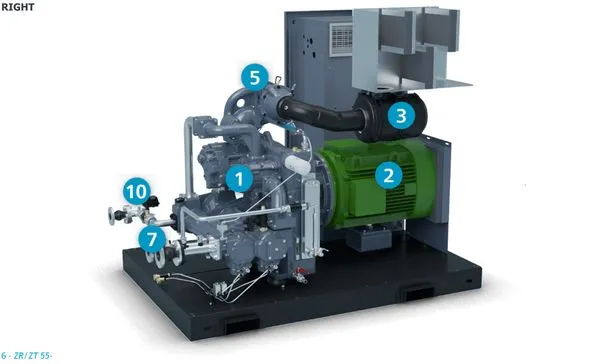

ZR 90 VSD FF

|

|

|

| 1.Oil-free air compressor elements (Class 0) • Unique seal design guarantees certified oil-free air • Superior coating for high durability • Cooling jackets to ensure world class compression in different conditions |

2.Main drive motor • IP55 TEFC motor protects against dust, chemicals and humidity • Continuous operation under severe ambient conditions |

| 3.Efficient intake air filtration • 2 stage dust removal system (99.9% for 3 micron) • High grade protection of the compressor |

4.Highly reliable coolers • Compact design with low approach temperature • Low thermal stresses ensure long lifetime • Reliable water separation ensures low water carry over to downstream equipment • Stainless steel water coolers designed for durability and easy serviceability |

| 5.Reliable load/unload regulation • No external air supply needed • Mechanical interlock of inlet and blow-off valve • Low unload power |

6.Advanced touch screen monitoring system • User friendly Elektronikon Touch with enhanced connectivity potential • Integrated smart algorithms to protect equipment in harsh conditions • Including warning indications, maintenance scheduling and online visualization of the machine’s condition |

| 7.Complete Plug-and-play package • All in one solution: fault free installation, easy commissioning and quick start up • Includes internal piping, coolers, motor, drive, lubrication and control system |

8.Sound proof design • Silenced canopy ensures optimal working conditions for everyone in the immediate environment • Optimized internal ducting and integrated pulsation damper to reduce noise level |

| 9.Ease of maintenance • Minimal service time with service parts grouped together for ease of access • All components are designed for serviceability and longevity • Optional service plans available to extend warranty |

10.Integrated dryer • With the ZR/ZT you have the option to include a dryer. IMD dryer with Silicone free rotor. |

Optimize your system

With the ZR, Atlas Copco provides an all-in-one standard package incorporating the latest technology in a built to-last design. To further optimize your ZR/ZT’s performance or to simply tailor it to your specific production environment, optional features are available.

| ZR 55-90 (VSD) | |

| Monitoring & Protection bundle (Anti-Condensation heaters / Monitoring & Protection bundle (Anti-Condensation heaters / SPM equipment / PT 1000 in the windings & bearings) | • |

| Integrated SMARTLINK | • |

| Kit for purge of dry air during standstill | • |

| Silicone-free rotor for dryer | Standard scope |

| Anchor pads | • |

| Wooden case protection packaging | • |

| High ambient temperature version* | • |

| Test certificate | • |

| Witnessed performance test | • |

| IT Network (VSD) | • |

| Energy recovery | • |

| Teflon free | • |

| MD heater | • |

| Hot air | • |

| Water shutoff valve | • |

• Optional

* Maximum intake/cooling air temperature is 50°C/122 °F for HAT versions. Please note the availability of the option depends on the chosen configuration.

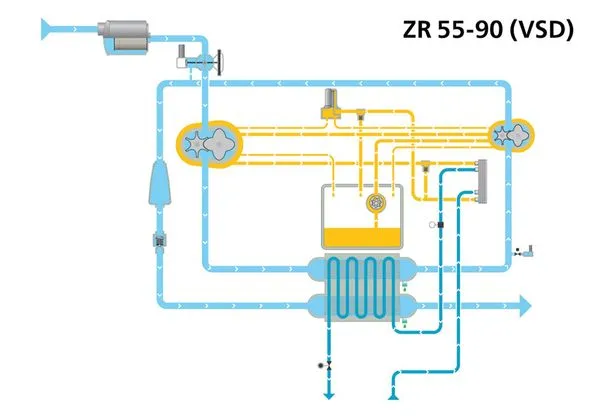

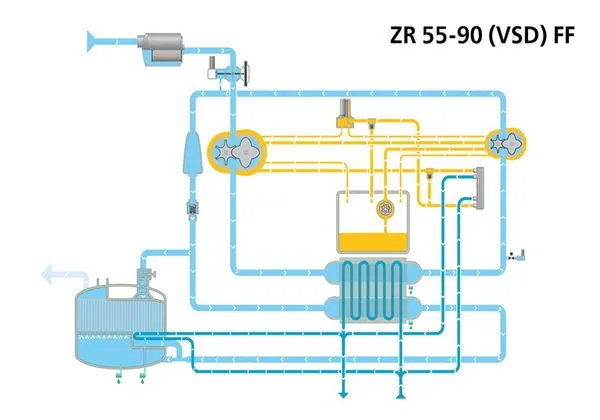

Atlas Copco ZR 55-90 (VSD) (FF) Oil-free Air Compressor Flowchart

|

|

|

| 1. Filtration & first compression The light blue flow represents the air. Air is drawn into the compressor through the inlet filter where the air is cleaned. Then passes through the throttle valve with integrated blow off valve that takes care of the load unload regulation. In the first compression stage the air pressure is raised to the intermediate pressure after which the air is cooled down in the inter-cooler. |

2. Cooling & second compression After the inter-cooler the air passes through a moisture separation system before entering the high pressure stage. In the high pressure stage the pressure is brought to the final pressure. |

| 3. Cooling & drying The air at the outlet of the high pressure stage is split in two parts. One part goes via the pulsation damper with integrated check valve to the after-cooler where it is cooled down and moisture is separated and evacuated. A second part goes directly to the regeneration area of the heat compression MD dryer.In the regeneration area of the dryer the hot air regenerates the adsorption drum after which it passes through the regeneration cooler where it is cooled down and moisture is separated and evacuated. The cold air coming from the regeneration section is then mixed with the cold air from the after-cooler in the nozzle-ejector system before passing through the drying section of the adsorption drum where the moisture is removed. Dry air leaves the compressor through the outlet connection flanges. |

4. Oil flow The yellow flow is the oil path within the compressor where the oil pump sucks oil from the oil sump and pumps it through the oil cooler and a high efficiency filter to give cool clean oil to the bearings and the gears; then the oil flows back to the gear casing. |

Technical Specifications

ZR 55-90 (FF) 50Hz

| Type | Working pressure (1) | Free Air Delivery (2) | Installed motor power (3) | Noise level (4) | ||

| bar(e) | l/s | m鲁/min | kW | dB(A) | ||

| ZR 55 | Minimum | 7.5 | 169.9 | 10.2 | 55 | 71 |

| Effective | 8.6 | 156.3 | 9.4 | |||

| Maximum | 10 | 140.7 | 8.4 | 74 | ||

| ZR 75 | Minimum | 7.5 | 224.6 | 13.5 | 75 | 69 |

| Effective | 8.6 | 214.7 | 12.9 | |||

| Maximum | 10 | 204.8 | 12.3 | 74 | ||

| ZR 90 | Minimum | 7.5 | 267.2 | 16 | 90 | 72 |

| Effective | 8.6 | 250.7 | 15 | |||

| Maximum | 10 | 263.4 | 14.2 | 74 | ||

ZR 55-90 (FF) 60Hz

| Type | Working pressure (1) | Free Air Delivery (2) | Installed motor power (3) | Noise level (4) | ||

| bar(e) | l/s | m鲁/min | kW | dB(A) | ||

| ZR 55 | Effective | 8.6 | 161.7 | 9.7 | 55 | 70 |

| Maximum | 10 | 142.7 | 8.6 | 74 | ||

| ZR 75 | Effective | 8.6 | 226.1 | 13.6 | 75 | 70 |

| Maximum | 10 | 200.3 | 12 | 74 | ||

| ZR 90 | Effective | 8.6 | 262.1 | 15.7 | 90 | 71 |

| Maximum | 10 | 240.8 | 14.5 | 74 | ||

ZR 75-90 VSD (FF)

| Type | Working pressure (1) | Free Air Delivery (2) | Installed motor power (3) | Noise level (4) | ||

| bar(e) | l/s | m³/min | kW | dB(A) | ||

| ZR 75 VSD – 8.6 | Minimum | 4 | 75.6 – 239.5 | 4.6 – 14.4 | 75 | 70 |

| Effective | 7 | 74.7 – 229.4 | 4.48 – 13.8 | |||

| Maximum | 8.6 | 74.1 – 208.6 | 4.4 – 12.5 | |||

| ZR 75 VSD – 10.4 | Minimum | 4 | 82.6 – 239.2 | 4.3 – 14.35 | 74 | |

| Effective | 9 | 81.7 – 202.9 | 5.0 – 12.2 | |||

| Maximum | 10.4 | 81.3 – 184.6 | 4.9 – 11.1 | |||

| ZR 90 VSD – 8.6 | Minimum | 6 | 75.1 – 297.2 | 4.51 – 17.8 | 90 | 71 |

| Effective | 7 | 74.1 – 282.5 | 4.4 – 16.9 | |||

| Maximum | 8.6 | 73.6 – 258.1 | 4.42 – 15.5 | |||

| ZR 90 VSD – 10.4 | Minimum | 6 | 76.5 – 292.9 | 4.6 – 17.6 | 74 | |

| Effective | 9 | 75.5 – 250.5 | 4.53 – 15.0 | |||

| Maximum | 10.4 | 75.0 – 229.2 | 4.5 – 13.7 | |||

(1 + 2) Unit performance measured according to ISO 1217, Annex C & E, Edition 4 (2009). Reference conditions: relative humidity 0%, absolute inlet pressure: 1 bar (14.5 psi), intake air temperature: 20°C (68°F). Free Air Delivery (FAD) is measured at the following working pressures: 7.5 bar versions at 7 bar, 8.6 bar versions at 8 bar, 10 bar versions at 9.5 bar. For VSD at 7 bar. For the working pressure of the FF variant, please contact Atlas Copco.

(3) The installed motor power might deviate depending on the options, voltages and pressure variants.

(4) A-weighted emission sound pressure level at the work station (LpWSAd). Measured according to ISO 2151: 2008 using ISO 9614-2 (sound intensity scanning method). The added correction factor (+/- 3 dB(A)) is the total uncertainty value (KpAd) conform with the test code.

Brochure

If you need Atlas Copco ZR 55-90 (VSD) (FF) oil-free rotary screw air compressors brochure, please click the link below to view or download it.

Atlas Copco ZR ZT 55-90 (VSD) (FF) oil-free rotary screw air compressors

| Weight | 1500 kg |

|---|---|

| Dimensions | 300 × 160 × 180 cm |

| 1-9 Pcs | $20000.00 |

| ≥10 Pcs | $15000.00 |

| Country of Origin | CN |

| Delivery Time | 60-90 Days |

| MOQ | 1 Piece |

| Packing | Wooden Crate |

| Product Quality | Brand-New Original |

| Transaction Mode | CFR, CIF, DAP, DDP, DPU, EXW, FCA, FOB |

Anonymous_buyer –

The ZR55 VSD FF performance has been outstanding

We have been using the Atlas Copco ZR 55 VSD FF Oil-free Air Compressor from BOAO for several months, and the performance has been outstanding. The oil-free air quality fully meets our production requirements, especially for sensitive applications. The VSD system adjusts smoothly to demand changes and significantly reduces energy consumption. Noise levels are low, and the FF design makes operation and maintenance much easier. Overall, it is a reliable, efficient, and well-engineered compressor that delivers consistent results in daily operation.